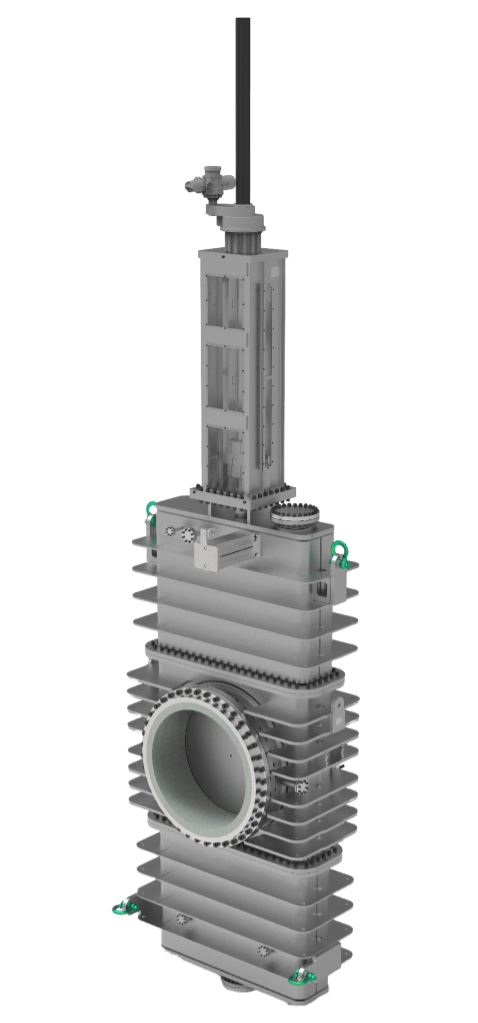

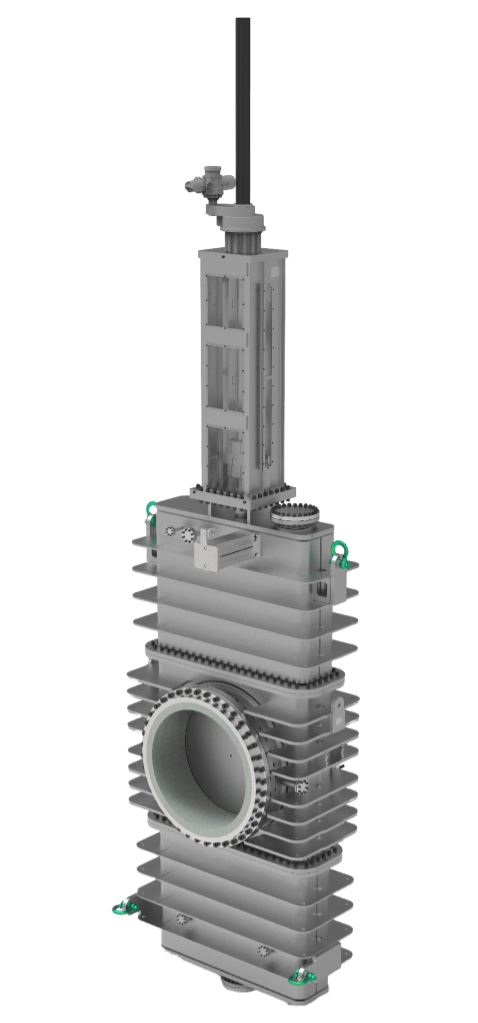

Fluidised Catalytic Cracking Unit Fractionator Isolation Valves

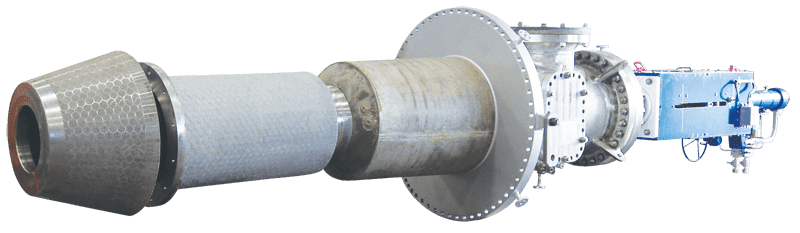

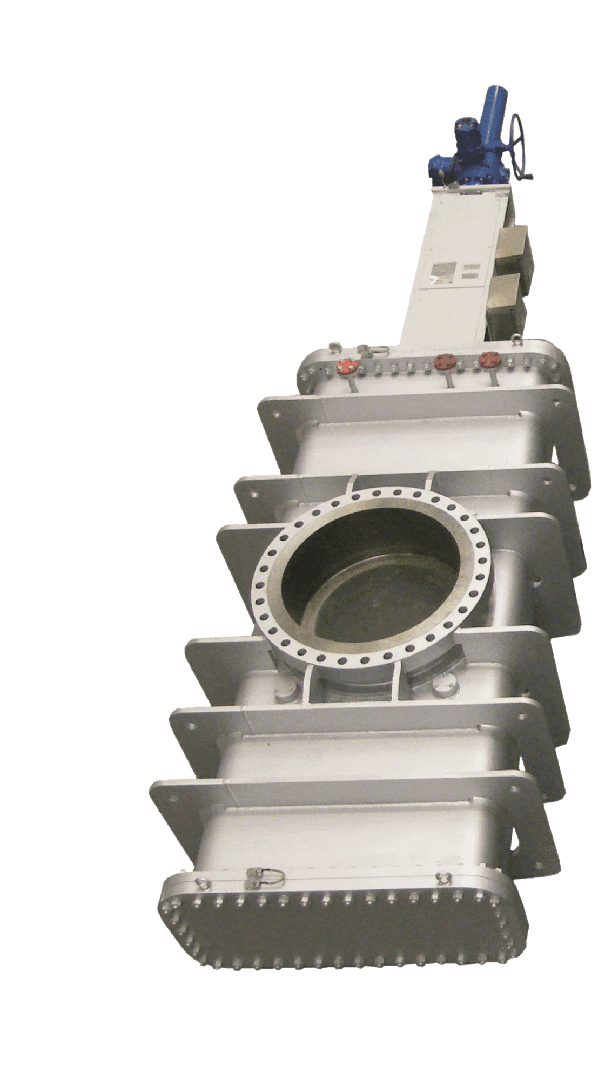

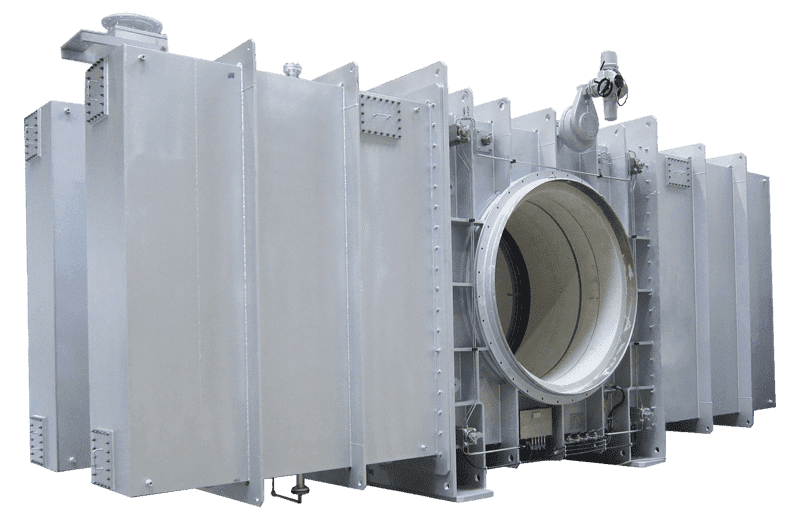

Double disc through conduit – double block and purge

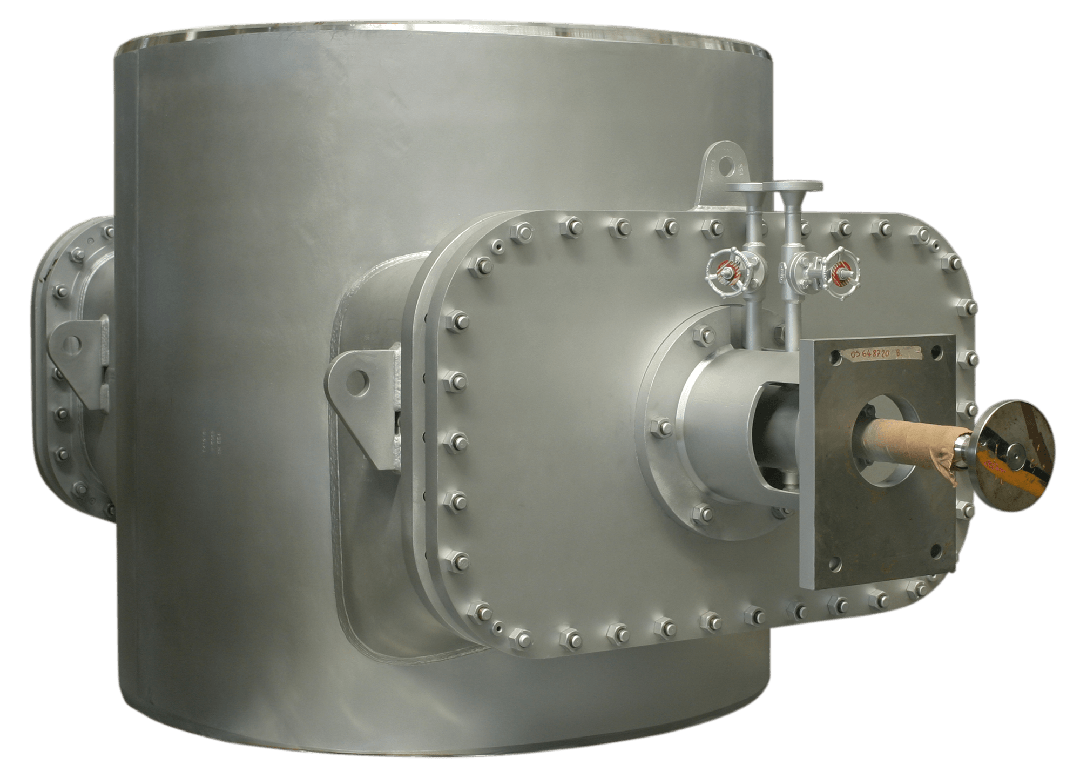

IMI Z&J’s Fluidised Catalytic Cracking Unit Fractionator Isolation Valves are based on proven double disc and double isolation valve designs. These valves are engineered to meet the stringent requirements of fluid catalytic cracking (FCC) processes, ensuring safe and reliable isolation of the fractionator.

- Double block and purge shut-off: Automatic line blind functionality for safe isolation.

- Erosion protection: Disc and body seats protected from erosion and coke media in both open and closed positions.

- Clean internal components: Valve cavity remains clean, free from process media buildup.

- Flexible mounting orientations: Available in horizontal, vertical, and other mounting configurations.

- Robust construction: Reinforced valve body designed to withstand project-specific line loads.

- Customised connections: Available in welded-in, flanged, or customised line connections.

- Material selection: Tailored to specific operational and design conditions for optimal performance.

Product Specifications

Dimensions

- Sizes from 6″ to 100″

Actuator types

- Electric

Purge media

- Steam

- Nitrogen

Ambient temperature

- -40°C (-40°F) to 60°C (140°F)

Leakage rate

API 598

Find your perfect flow control solution