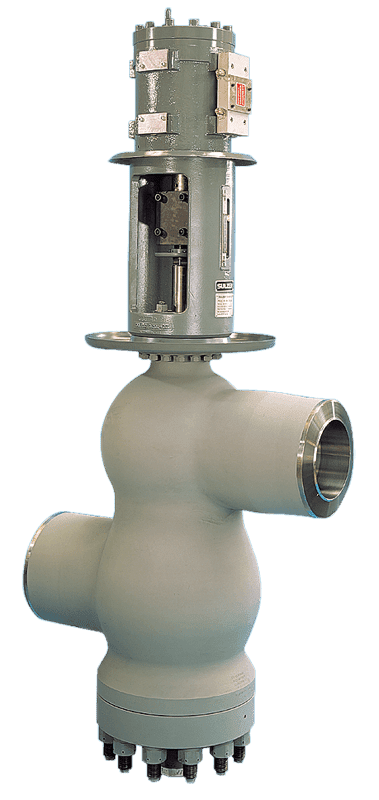

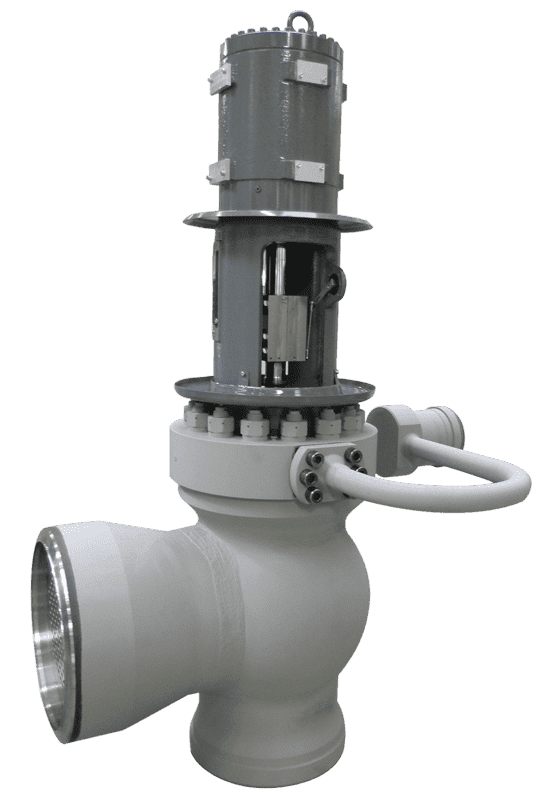

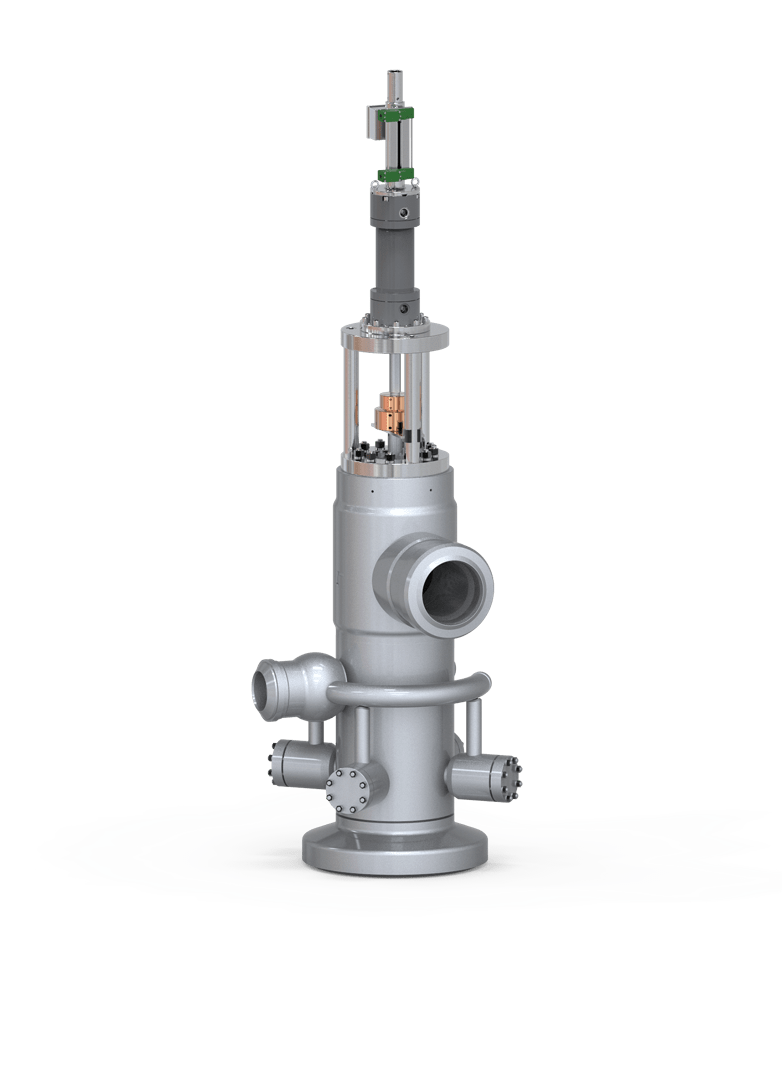

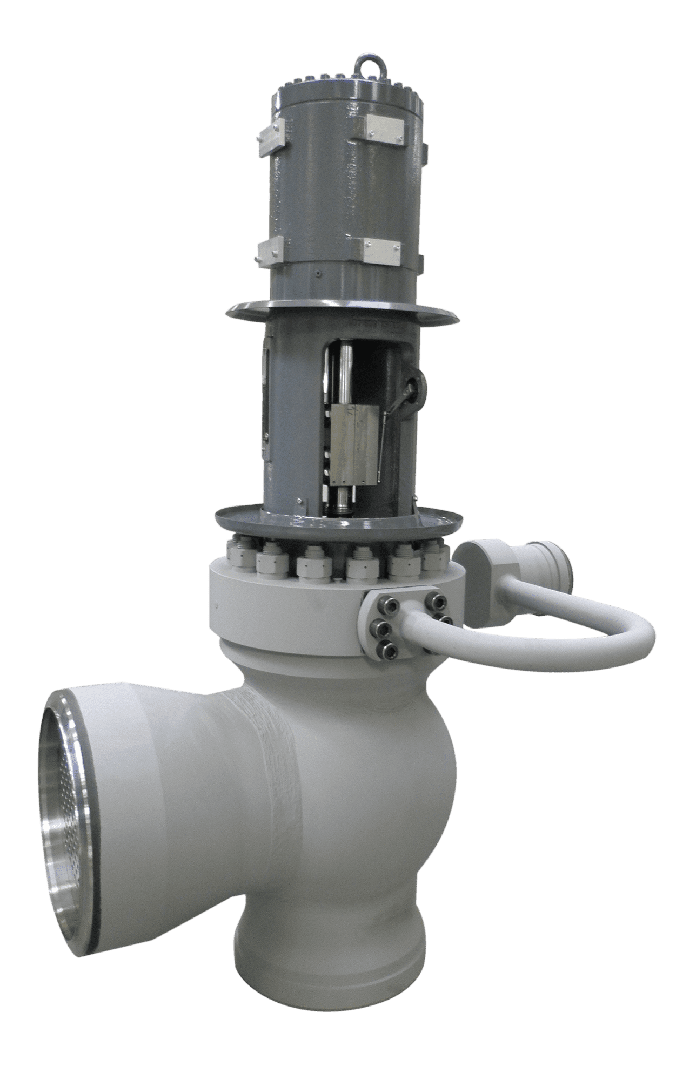

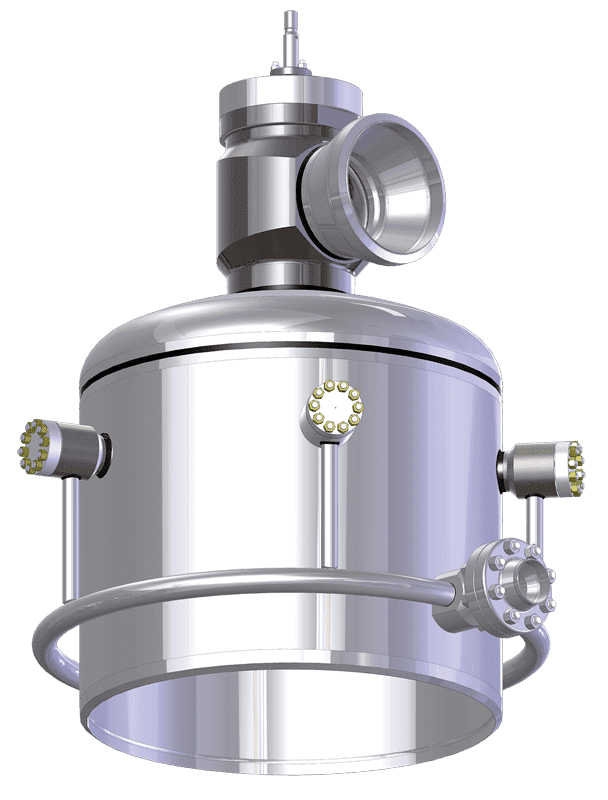

VS Turbine Bypass Stop Valve

High-performance turbine bypass stop valve for harsh environments

The VS Turbine Bypass Stop Valve is designed for use in the demanding conditions of modern fossil-fuelled power plants. It is commonly applied when a separate stop valve is required upstream of the HP or LP turbine bypass valves, or when a tight shut-off valve is necessary. Additionally, the VS valve can be utilised in the spray water line, or as an isolation valve in a process steam line. Its robust construction ensures long-term performance in harsh environments, making it a reliable solution for critical operations.

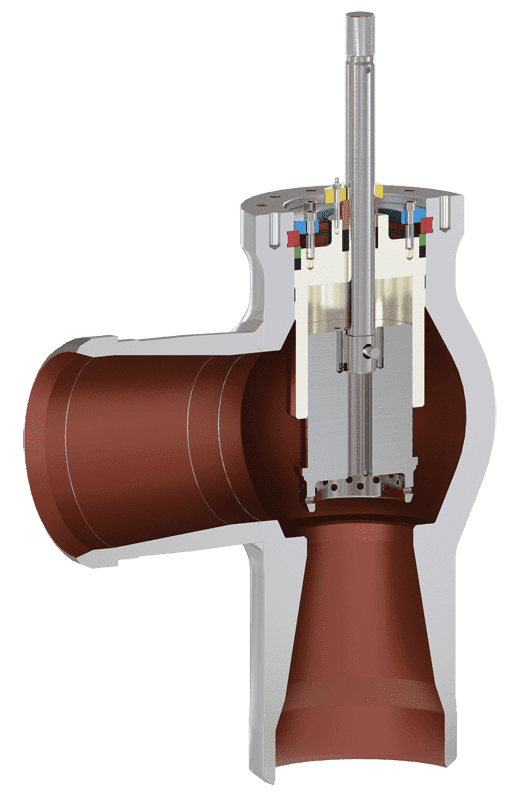

- Fully machined valve body made from forged CrMo low alloy or carbon steel to minimise material stresses and ensure durability.

- Angle-style valve design for superior flow control and structural strength.

- Hard-faced seat integrated with the valve body, providing Class V (ANSI/FCI 70-2) tightness and eliminating the need for gaskets.

- Pressure seal bonnet design for easy mounting and removal, ensuring safe and secure operation.

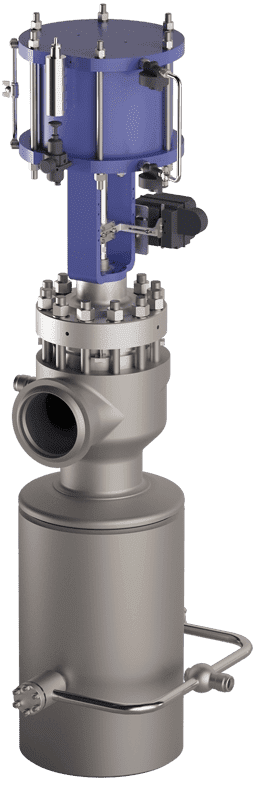

- Customisable design with options for pneumatic, electrohydraulic, or electromechanical actuators based on project requirements.

- Available in balanced tight design to reduce opening forces and improve efficiency.

Product Specifications

Valve configuration

- VS-T: Unbalanced, tight design with leakage tightness according to ANSI B16.104 Class V.

- VS-BT: Balanced, tight design with leakage tightness according to ANSI B16.104 Class V.

Actuator options

- Pneumatic actuator

- Electrohydraulic actuator

- Electromechanical actuator

Materials

- Valve body: Forged CrMo low alloy or carbon steel

- Plug and stem: Corrosion-resistant alloy with surface treatment for added hardness

Find your perfect flow control solution