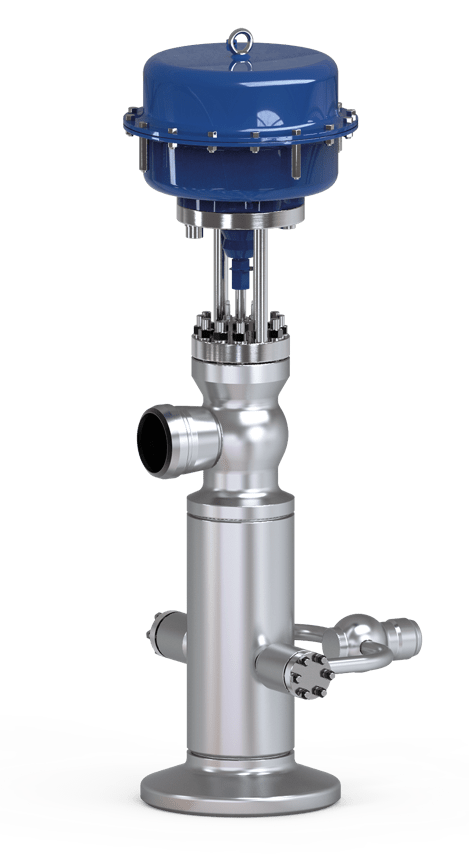

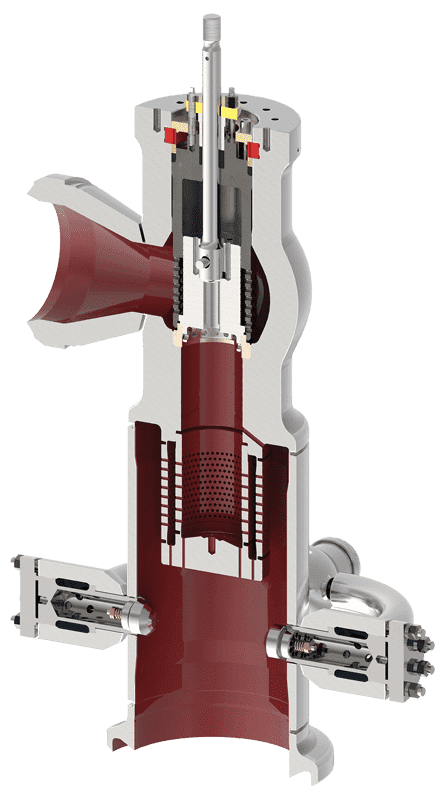

VLB Steam Conditioning Valve

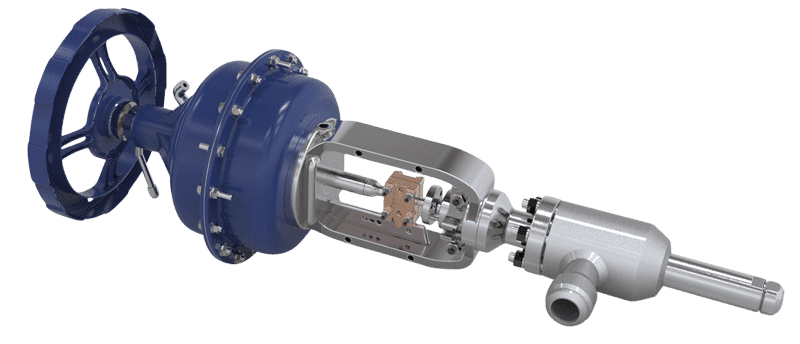

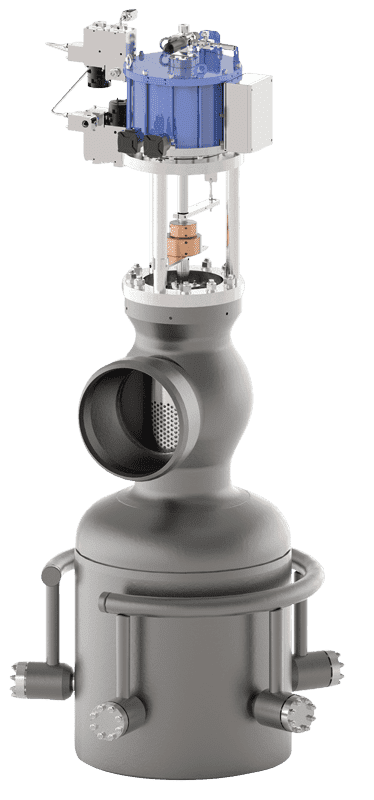

The VLB is an angle-style steam conditioning valve, used for high/low pressure turbine bypass or as a process valve. It regulates both steam pressure and temperature, reducing it from a higher-pressure system to match the requirements of a lower-pressure system. The valve is equipped with multiple pressure reducing stages and an integrated desuperheating stage at the outlet to ensure optimal performance.

Key features

- Multi-stage pressure reduction for controlled flow and noise abatement.

- Integrated spray water injection for efficient desuperheating at the outlet.

- Homogeneous forged valve body to minimise thermal stress.

- Customisable inlet and outlet connections to fit customer steam pipes.

- Balanced tight design available to reduce required opening forces.

Product Specifications

Valve sizes

Available in sizes from 50 mm to 500 mm seat diameter. Custom sizes can be provided on request to meet specific system requirements.

Pressure class

Supports pressure ratings up to ANSI-4500. Higher pressure ratings can be supplied upon request for high-pressure systems.

Design temperature

Rated to withstand design temperatures of up to 650°C, ensuring durability and performance in high-temperature environments.

Leakage class

Certified to ANSI Class V/MSS SP-61 leakage class, providing secure shut-off and minimal leakage during operation.

Materials

The valve body and other critical components are manufactured from forged materials, carefully adapted to match the connecting pipe materials for durability and compatibility.

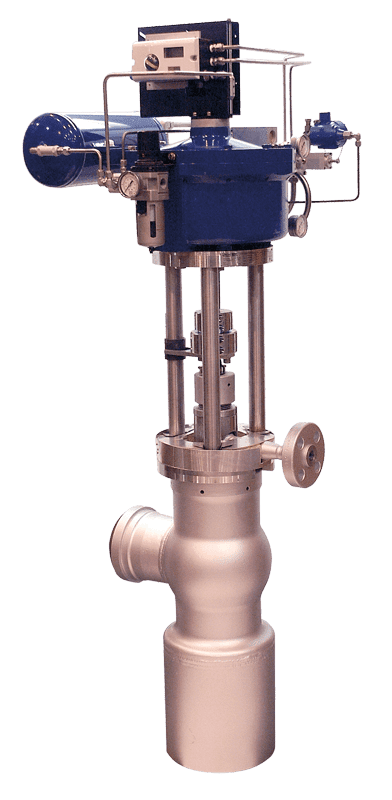

Actuation

Available with electrical, hydraulic, or pneumatic actuation options to suit different system control requirements.

Find your perfect flow control solution