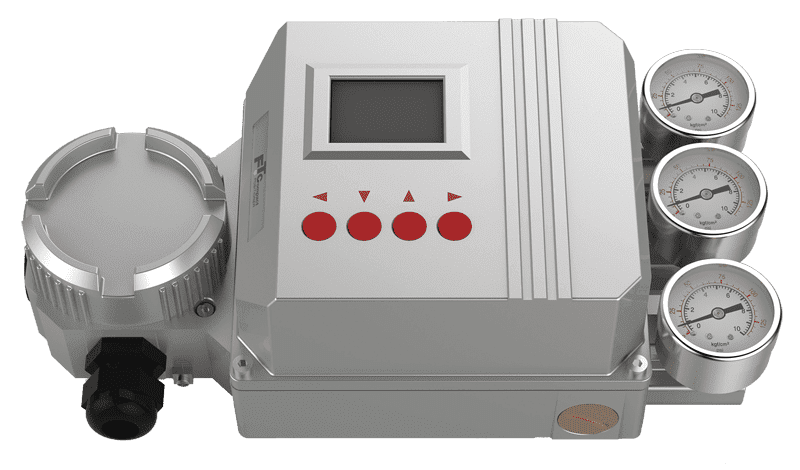

High Precision Digital Pneumatic Valve Positioner (SHP)

The Smart High-Performance (SHP) Valve Positioner delivers unique dynamic valve control and advanced diagnostics

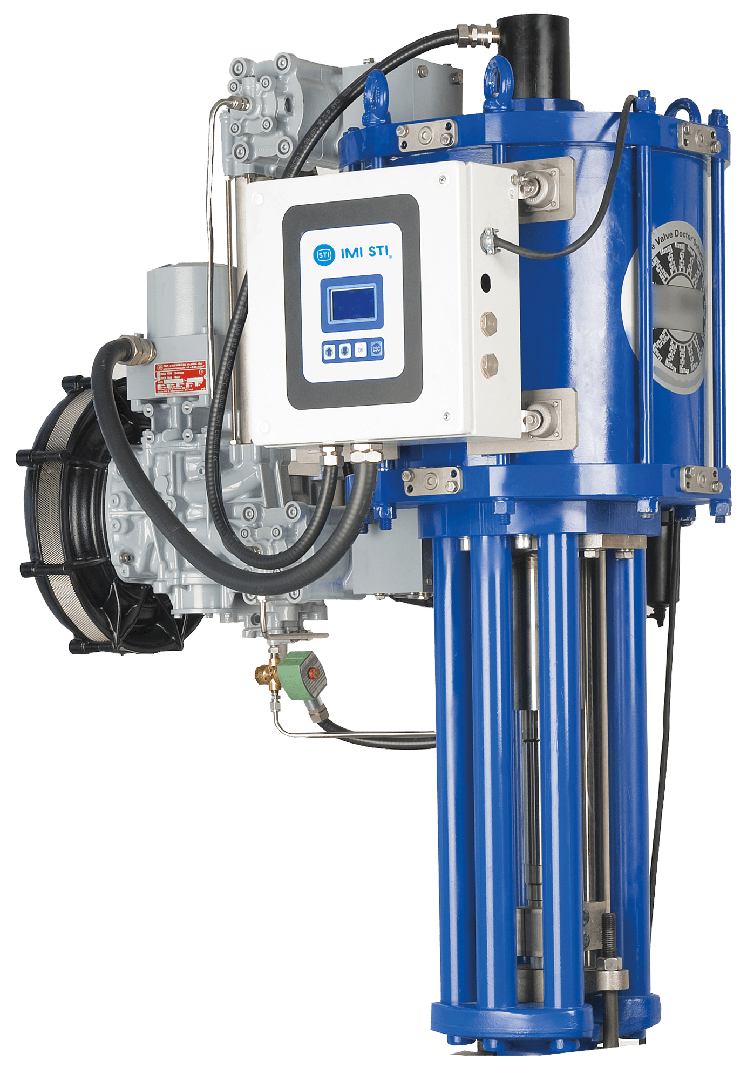

The Smart High-Performance (SHP) Positioner is a high capacity and high precision digital pneumatic valve positioner, mainly used as a valve care controller that replaces or substitutes the existing FT Positioner. Its flow rate and control algorithm system and logic, patented by IMI STI, ensure unique dynamic performance and low stroking time. Its advanced diagnostics (online and offline) have been specifically developed to meet all customer needs.

- High-speed performance for large volume actuators, minimising amplification devices

- Contactless magnetic feedback sensor with excellent reliability and accuracy

- On-line diagnostics via event recorder, counters, logs, valve life prediction, and status monitoring

- Intrinsically safe and explosion-proof certifications

- Connectivity via remote software, HART 7, USB, and FDI driver

- Local user interface with display and keyboard

- Off-line diagnostics via ramp, step, signature, and frequency tests

- Control capabilities for various actuator types and actions

SHP Valve Positioner Specifications

Hardware

- Housing: stainless steel ASTM A351 / low copper aluminum EN AC 43500.

- Total weight < 9kg (stainless steel) / < 4kg (aluminum).

- Total dimensions less than 190mm x 120mm x 145mm.

- Mechanical interface for fixing screws according to VDE/VDI 3845 (NAMUR).

- Pneumatic connections: 3 x ½” NPT female.

- Electrical connections: 3 x ½” NPT female (Ex ia) / 1 x ½” NPT female (Ex d).

Electronic positioner

- Communication protocol HART 7, 4-20mA.

- Input voltage range = 10-30V (Ex ia) / 18-30V (Ex d) / 17V-30V (Ex ia fail freeze application).

- Impedance < 500Ω (Ex ia) / < 900 Ω (Ex d) / < 850 Ω (Ex ia fail freeze application).

- Output signal 4-20mA passive loop.

- Digital input 24V isolated qty 2 configurable.

- Digital output 24V isolated qty 2 configurable (qty 2 NPN or qty 1 NAMUR), external power supply needed.

- Electric consumption < 1W.

- Electronic internal loop update rate = 10ms.

- Analog output update rate = 10ms.

Pneumatic positioner

- Operating pressure range = 2.5 / 10.4bar – 150PSI (fail freeze 8bar, natural gas 6bar).

- Design pressure = 15bar / 220PSI.

- Instrument air / natural gas / nitrogen / sweet and dry gases, according to ISO 8573-1 class 3 (oil concentration) and class 6 (dust concentration).

- High Flow → Supply Cv max = 2.3 / Exhaust Cv max = 2.3 (180Nm3/h @ 6bar / 21 °C).

- (Air consumption ≤ 1.5Nm3/h @ 6bar / 21 °C).

- Low Flow → Supply Cv = 0.3 / Exhaust Cv = 0.3.

Performance

- Quick action = 100ms (time needed to achieve Cv max starting from Cv = 0).

- Hysteresis + Dead band = +/- 0.10%. (*)

- Repeatability = +/- 0.05%. (*)

- Sensitivity = +/- 0.10%. (*)

- Linearity = +/- 0.30%. (*)

- Thermal drift from -55°C to +85°C < 0.4%. (from -40°C to +85°C < 0.1%).

(*) @ 21°C / 120° rotation.

Position feedback

- Contactless sensor into positioner, able to work 360° rotation.

- Remote contactless sensor (option), up to 20m distance from the positioner.

- Linear magnet kit (option) available when strokes up to 100mm / 4 inch.

Applications

- Fail safe (Pneumatic connection A vent / B pressurised).

- Fail freeze (N/A with Ex d certification), with piezo valve and dedicated 3-way valve.

Environment

- Operating temperature range = -55°C / +85°C, see Ex certificate for T4 – T5 – T6.

- Storage temperature range = -55°C / +85°C.

- IP 66 / NEMA 4X.

Option packs

- Download brochure below to see various option packs

Find your perfect flow control solution