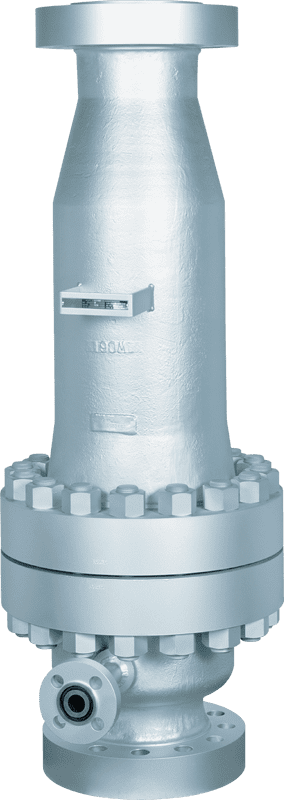

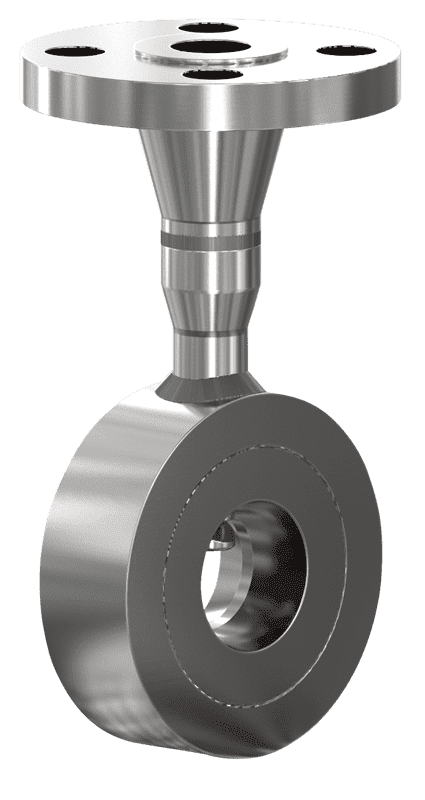

DAM-H High-temp Multi-nozzle Desuperheater

High-temp multi-nozzle desuperheater with floating liner

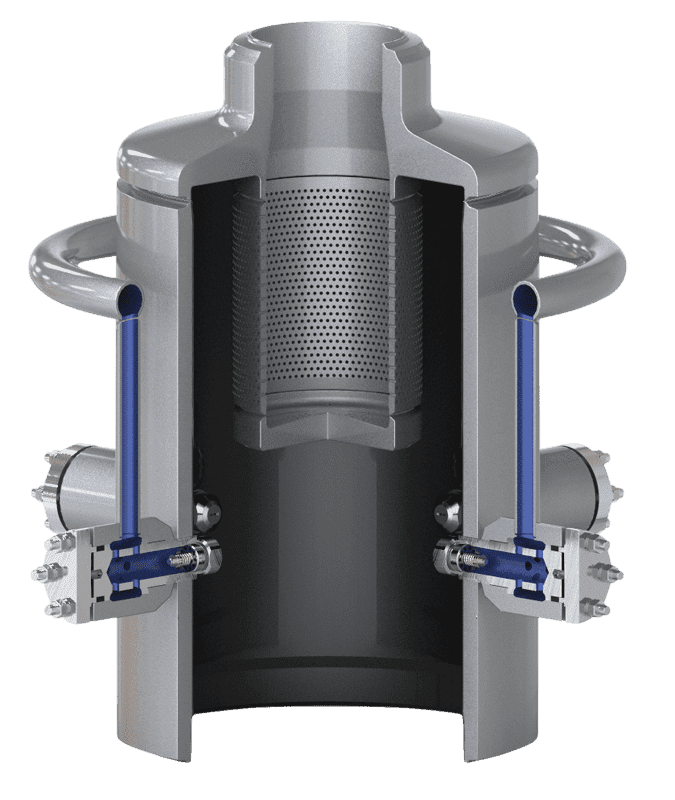

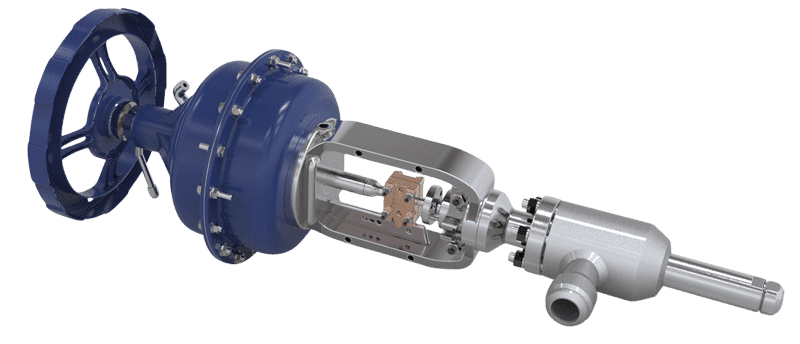

The DAM-H desuperheater is designed for attemperation in high-temperature applications, such as controlling the superheat degree in boilers or Heat Recovery Steam Generators (HRSG). This desuperheater features a controlled injection of water into the superheated steam, ensuring precise temperature control. Its floating flow profiling liner (patent pending) is designed to improve evaporation performance and handle thermal cycling, making the DAM-H a highly reliable solution for demanding steam systems.

- Floating flow profiling liner (patent pending) for enhanced evaporation performance.

- Designed to handle large spray water flow quantities efficiently.

- Even distribution of spray water within the steam pipe, ensuring reliable operation.

- Negligible pressure drop across the steam line.

- Nozzles designed to prevent flashing, enhancing operational safety.

- High resistance to thermal cycling for long-term durability.

Product Specifications

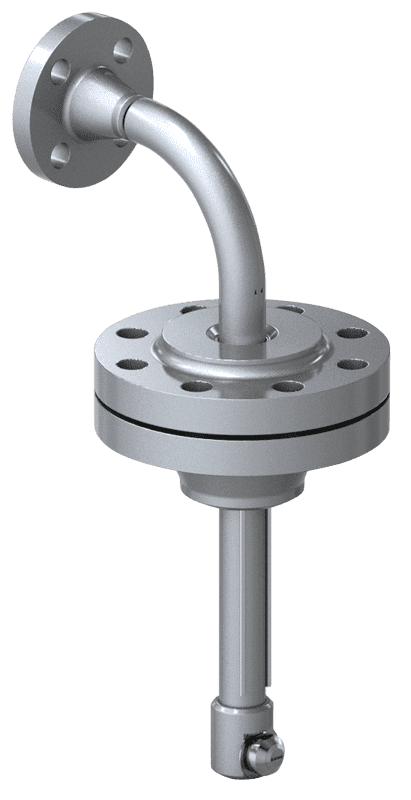

Nozzle

- Material: Inconel 718

- Rangeability: Determined by water valve

Regulatory requirements

- ASME, PED, S-Stamp

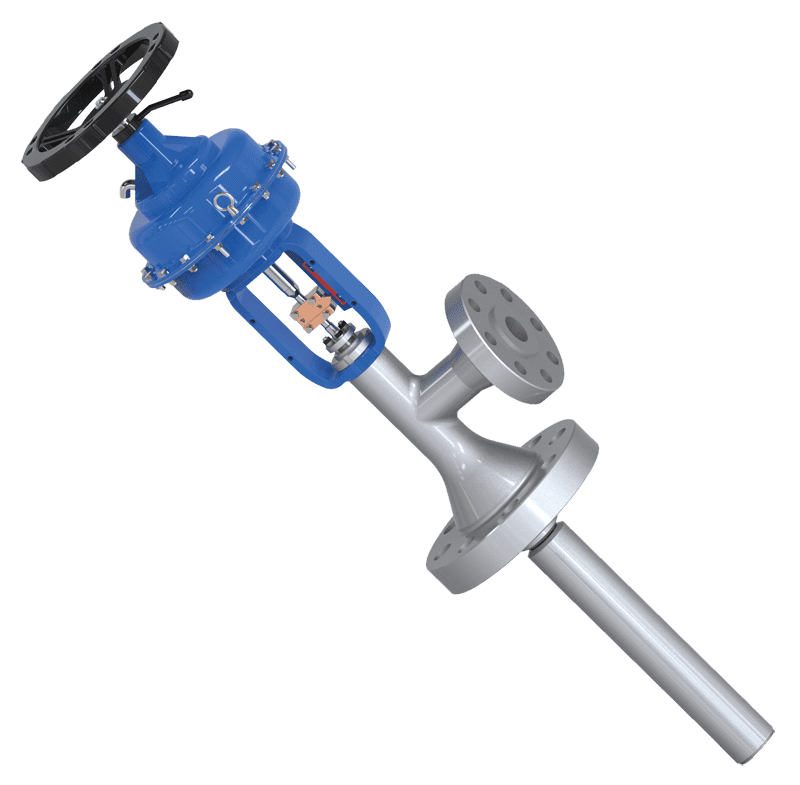

Steam connection

- Design Pressure: 200 bar(g)

- Design Temperature: 630°C

Water connection

- Design Pressure: 320 bar(g)

- Design Temperature: 250°C

Cycling

- Up to 6300 cycles / 25 years

Steam pipe sizes

- DN200 – DN700 (step size 50)

Installation

- Horizontal or vertical up is recommended.

- Vertical down may require additional configuration.

Find your perfect flow control solution