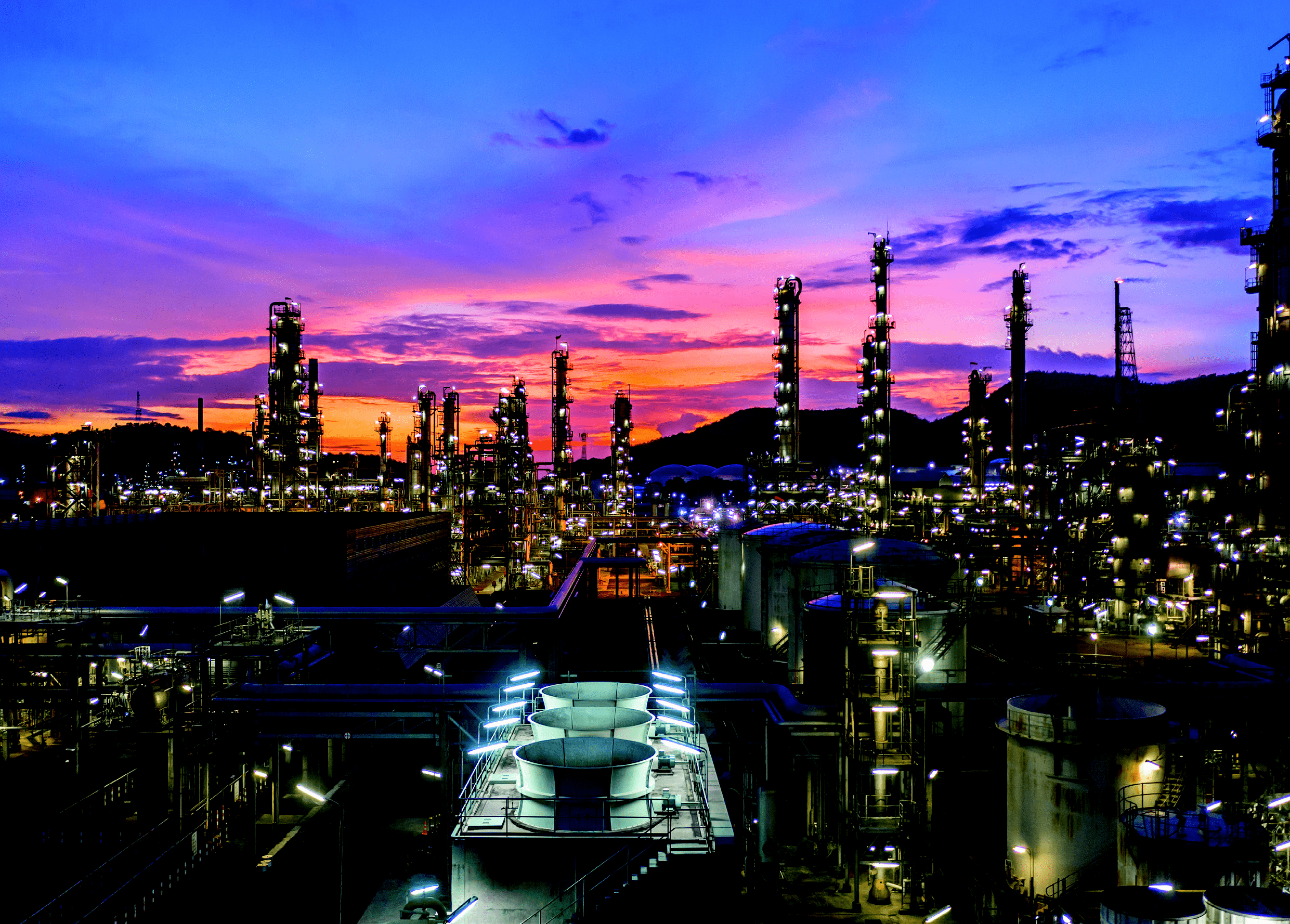

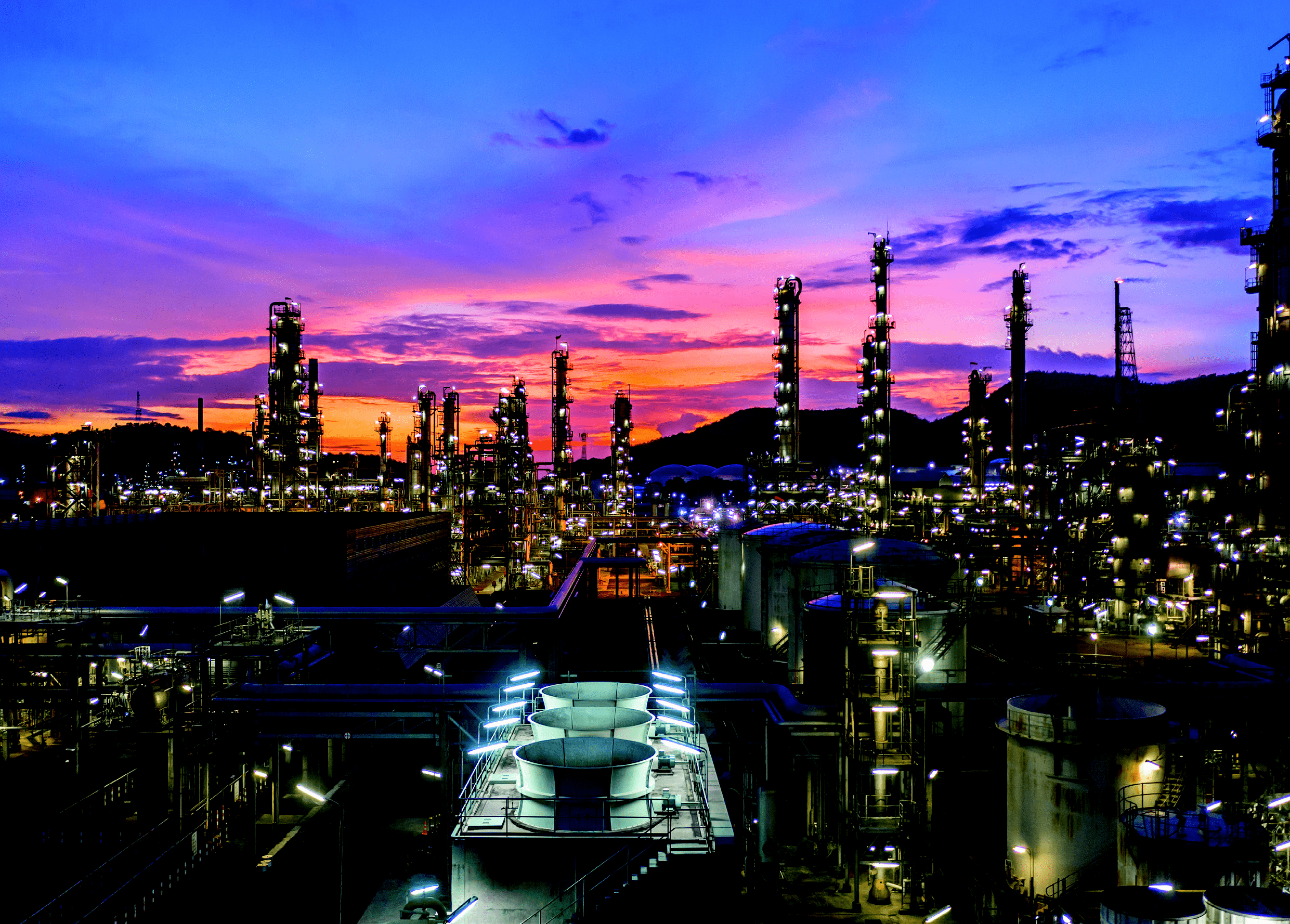

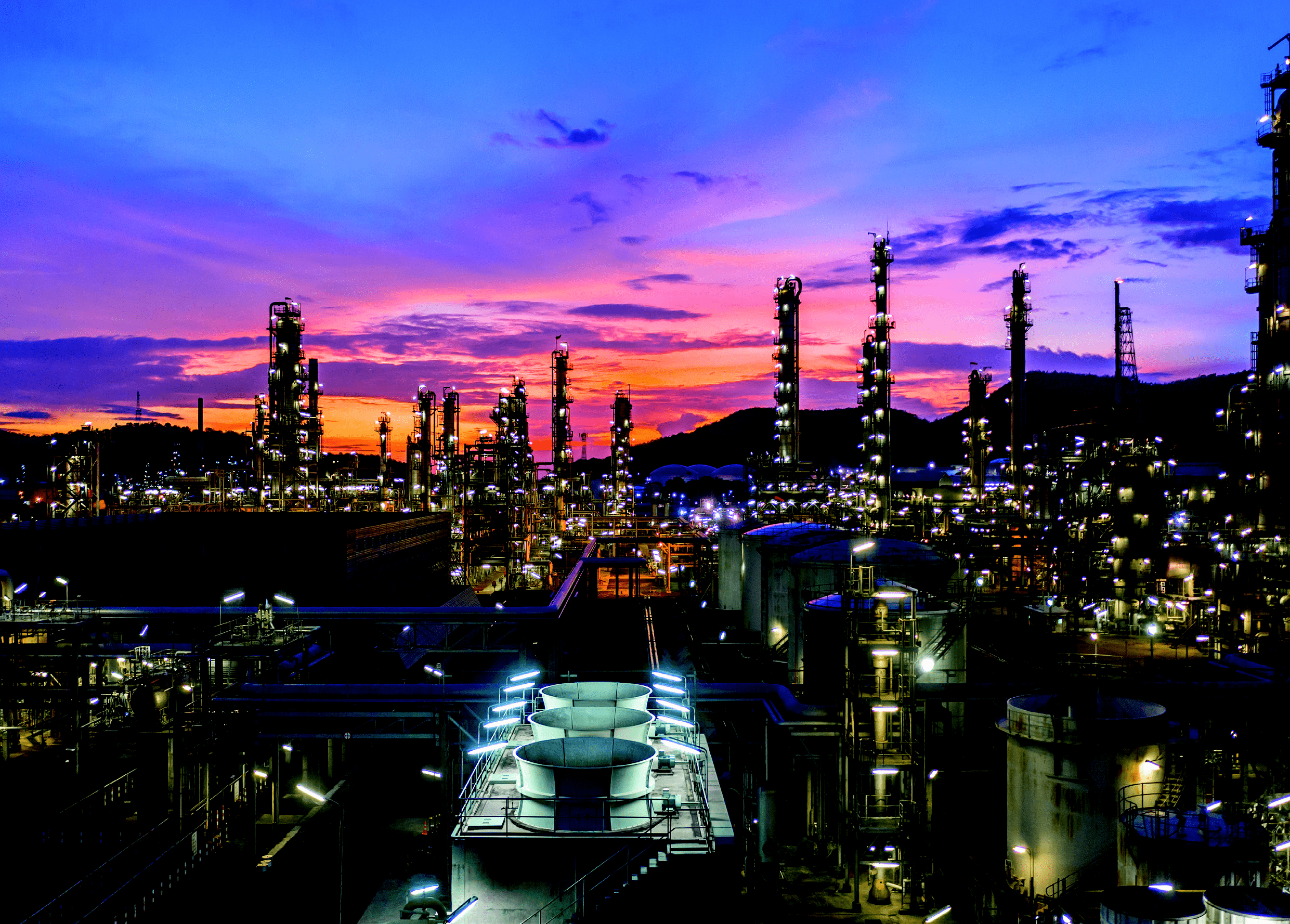

A major South Asian oil and gas customer needed to carry out comprehensive preventative maintenance on the IMI equipment installed on their refinery in Malaysia. IMI Remosa and IMI Z&J have an extensive base of installed valves in the refinery, with around 40 valves and actuating systems, ranging from slide/butterfly/diverter valves from IMI Remosa, through to Double Disc Through Conduit, Goggle and Special Check valves from IMI Z&J.

The client wanted to carry out maintenance across a wide number and types of equipment. However, this had become a very challenging ask during the uncertainties caused by the Covid-19 pandemic, and the client asked IMI how the maintenance could be carried out despite the constraints of the pandemic.

AR headset leaves the site engineer’s hands completely free to work on the hardware without obstruction.

IMI recommended that the maintenance programme be carried out in full using IMI’s remote assistance service, IMI Connect.

Connect was developed pre-pandemic to provide high-quality remote assistance in the field, by connecting a client’s on-site technicians to IMI’s valve experts anywhere in the world. Field technicians can connect to an IMI expert using a smart device – a smartphone or tablet, or a wearable augmented reality audio-visual headset. Once connected, IMI experts will supervise the maintenance or troubleshooting activity required. They can share screens, share photos and videos and add extra participants as needed. A hands overlay function allows IMI’s experts to show the field service technician exactly what to do and how to do it. The lightweight headset gives technicians a hands-free option.

The customer welcomed the flexibility of Connect, and the IMI teams in Europe and south-east Asia put together a team to deliver this extensive remote maintenance programme. A team comprising experts in Italy and Germany, including specialists in mechanics and control, delivered a total of 26 days of remote assistance on one of the world’s biggest refineries. Thanks to Connect, a comprehensive maintenance programme was completed, minimising plant downtime and maximising the efficiency of the process.

IMI Connect remote assistance is available for troubleshooting, as well as for planned and preventative maintenance.