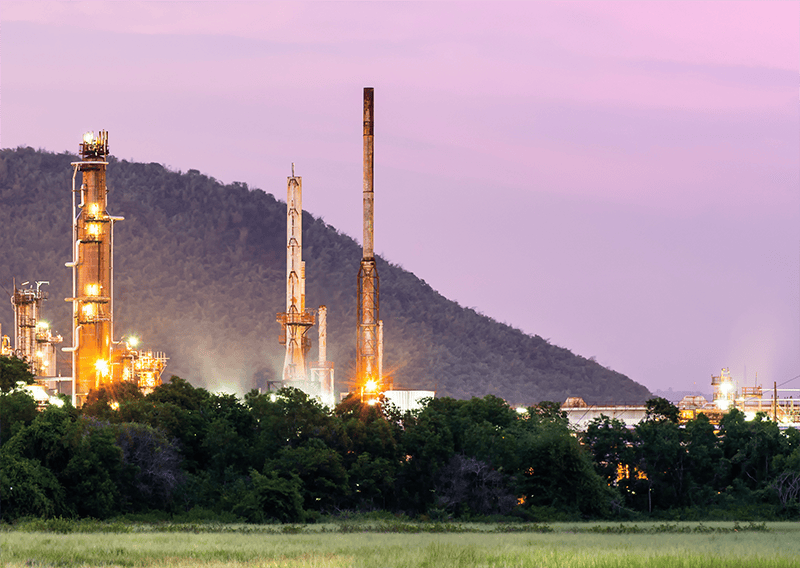

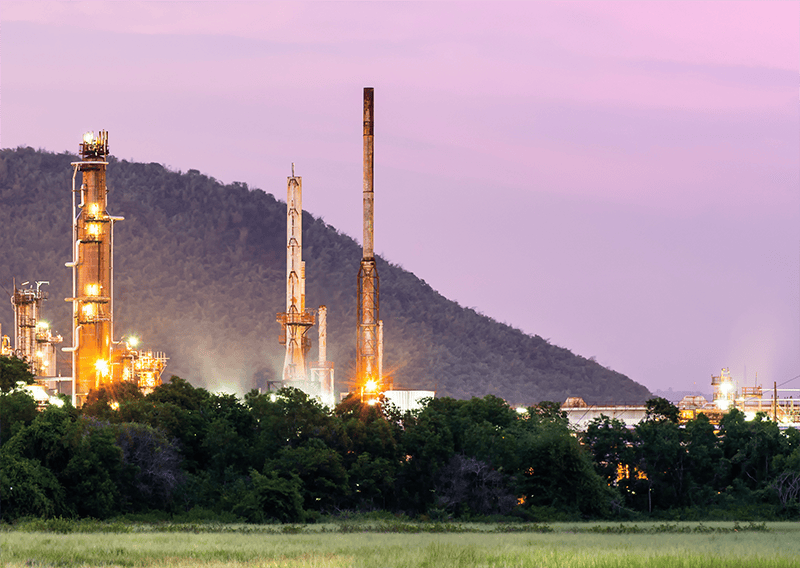

Scotland’s only oil refinery, Grangemouth Refinery, is set to close due to global market pressures, including declining demand and environmental regulations.

The closure of Grangemouth Refinery underlines the importance of upgrading existing plant components to facilitate the energy transition, says an expert in flow control solutions to the oil and gas sector.

Roby Buyung, President of Process Automation at IMI, comments: “Declining demand for fossil fuels and weakening refining margins are becoming increasingly common as countries move towards their respective net zero deadlines. In this challenging environment, legacy maintenance strategies and component upgrades are crucial to ensuring existing plants can remain as productive and competitive as possible for as long as possible.”

According to Mr. Buyung, a multifaceted approach to plant maintenance and asset upgrading, informed by the expertise of external OEMs, is key to effectively prolonging plant lifetimes. By following the guidance of industry experts when developing asset management and preventative maintenance strategies, refinery stakeholders can better guard against issues including expensive unplanned shutdowns or extended periods of key component maintenance.

“Decarbonisation continues apace across the world, yet fossil fuels will remain vital to many nations’ energy mixes for the short-to-medium term,” he concludes. “To best facilitate the ongoing energy transition and avoid premature closures such as Grangemouth, it is vital that legacy assets are as productive as possible.”

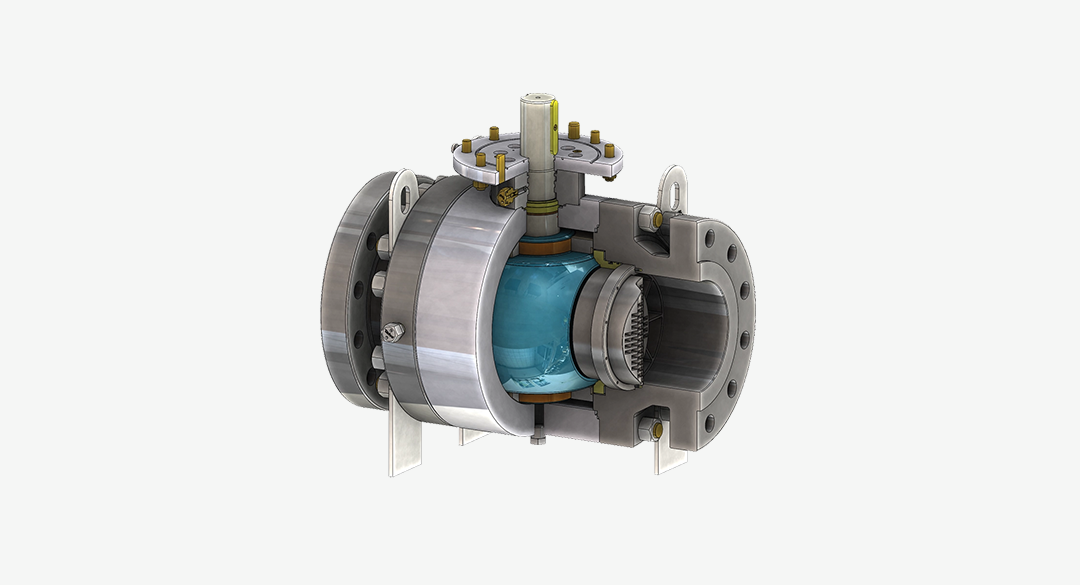

“This will require a proactive approach to component maintenance and a robust upgrades programme for the foreseeable future, as well as specification strategies for critical flow control components. By using existing expertise within the refinery supply chain, refinery stakeholders can better access technologies to assist in this aim, including real-time asset monitoring and augmented reality and audio-visual diagnostic remote assistance technologies.”

Explore how IMI can help optimise your plant’s performance with innovative technologies, real-time monitoring, and expert maintenance strategies. Click here to learn more about our oil and gas solutions designed to enhance operational efficiency.