With €3 billion in federal aid approved by the European Commission, the HCN aims to connect hydrogen production centres with industries that are challenging to electrify. However, while this ambitious pipeline network is central to Germany’s National Hydrogen Strategy, it is not a one-size-fits-all solution.

The HCN’s timeline is a key challenge. Converting natural gas pipelines to handle hydrogen safely—due to its embrittlement effect on metals—and constructing new infrastructure will take until 2032. This lengthy timeline clashes with Germany’s climate target of reducing greenhouse gas emissions by 65% compared to 1990 levels by 2030. Moreover, large infrastructure projects like the HCN are often prone to cost overruns and delays.

Decentralised hydrogen production offers a complementary and more immediate solution. By leveraging polymer electrolyte membrane (PEM) electrolysis, hydrogen can be produced on-site at industrial facilities. This approach reduces dependency on pipeline networks and eliminates many of the challenges associated with tanker deliveries, such as emissions, storage space requirements, and logistical inefficiencies.

IMI’s VIVO electrolyser exemplifies the potential of decentralised production. Delivered as a turnkey solution, it fits within the footprint of a standard shipping container. This scalability allows rapid deployment, enabling industries to produce hydrogen as needed, without the extensive storage or pressurisation systems required for tanker deliveries.

The HCN also faces geographic limitations. While it focuses on connecting high-energy industrial hubs, smaller but cumulative energy users remain unaddressed. Decentralised hydrogen generation empowers these dispersed users, offering tailored solutions that don’t rely on proximity to the pipeline network.

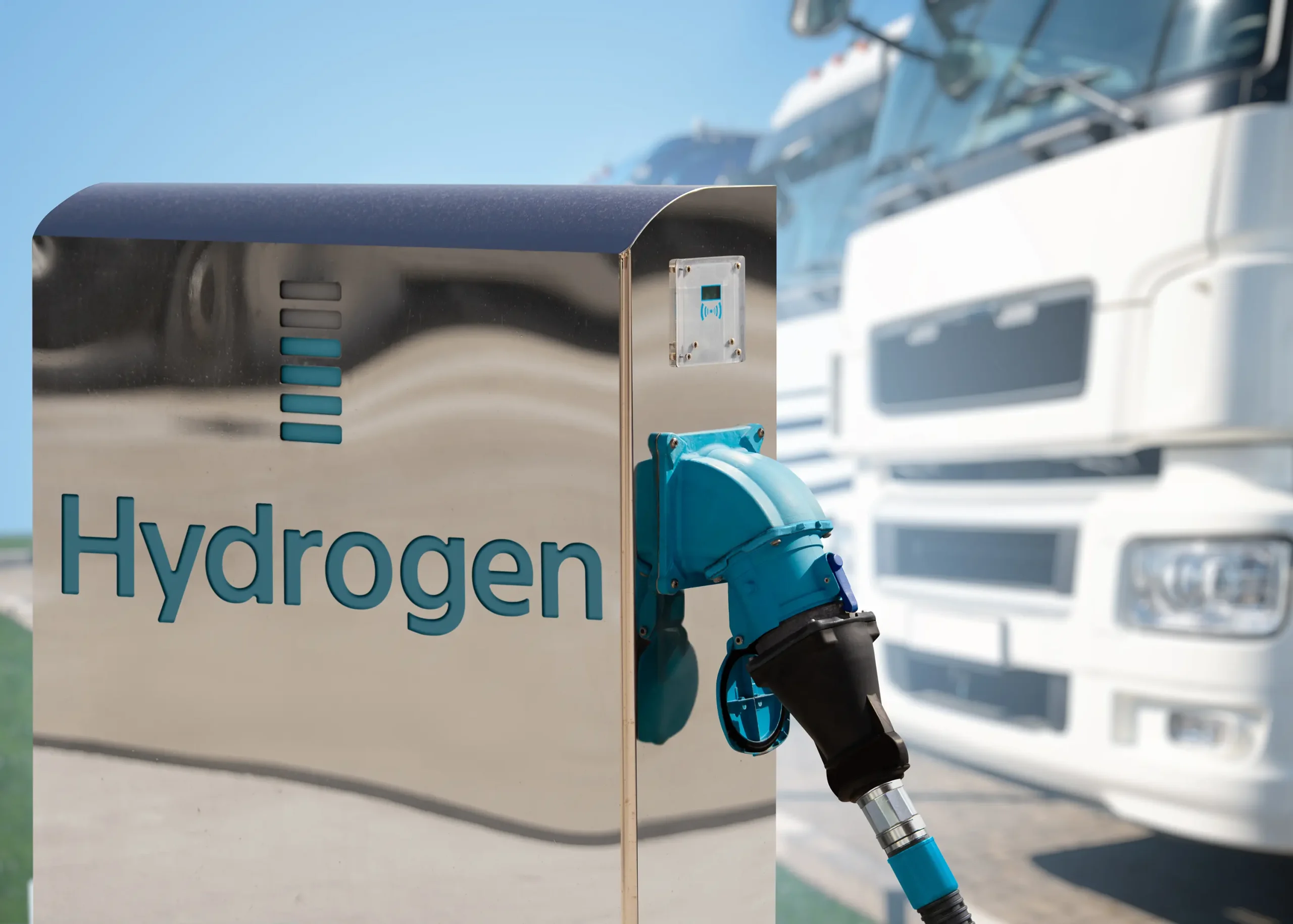

The transport sector, Germany’s second-largest source of CO₂ emissions, highlights another gap in the HCN’s approach. Battery-electric technologies, though promising, face challenges in long-distance haulage and high-uptime applications. Decentralised hydrogen production can fuel these operations without the need for extensive infrastructure, making it an ideal solution for the fragmented transport sector.

Decentralisation not only accelerates decarbonisation but also enhances supply security. Unlike centralised networks, on-site production eliminates the risk of cascading failures across interconnected systems. This resilience is critical for industries where uninterrupted operations are essential.

In conclusion, while the HCN is an important part of Germany’s decarbonisation strategy, it must be complemented by diverse approaches to hydrogen distribution. Decentralised hydrogen production addresses immediate needs, bypassing the delays and limitations inherent in large-scale infrastructure projects. Scalable solutions like the IMI VIVO electrolyser empower industries and transport operators to act now, bridging the gap between long-term plans and urgent climate goals.

By Dr. Cornelia Neumann

Sales & Business Development Manager, IMI

Power your transition to sustainable energy with IMI VIVO – IMI’s advanced PEM electrolysers and low-pressure hydrogen storage solutions. Designed for efficiency and reliability, our systems optimise green hydrogen production and storage. Partner with IMI today to build a cleaner, more sustainable future.