When it comes to plumbing and industrial applications, the choice of isolation valves can significantly impact system performance and reliability. An isolation valve is a crucial component that allows for the safe and efficient management of fluid flow, ensuring that maintenance and repairs can be conducted without disrupting the entire system. Selecting the best option among a myriad of choices can be daunting, but understanding the key features and functions of various isolation valves is essential for making an informed decision.

In this article, we explore the top 10 isolation valves that stand out in the market for their durability, efficiency, and ease of use. From traditional gate valves to advanced ball and butterfly designs, these valves cater to diverse operational needs and environments. By examining their unique attributes, applications, and materials, we aim to guide you through the best options for your specific plumbing or industrial requirements. Whether you are a seasoned professional or someone new to the field, this comprehensive overview will provide valuable insights into selecting the ideal isolation valve for optimal performance and reliability.

Isolation valves play a critical role in plumbing and industrial applications, allowing for the control and management of fluid flow within a system. These valves, which can be categorized into several types including gate, globe, ball, and butterfly valves, serve the essential function of isolating different segments of a system for maintenance or emergency purposes. According to a report by the Global Market Insights, the isolation valve market is projected to reach $20 billion by 2027, driven by the growing demand for advanced plumbing solutions in both residential and industrial sectors.

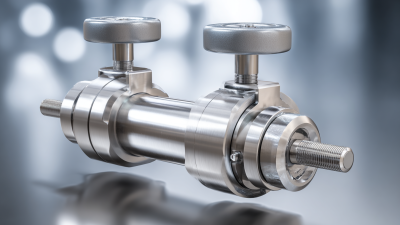

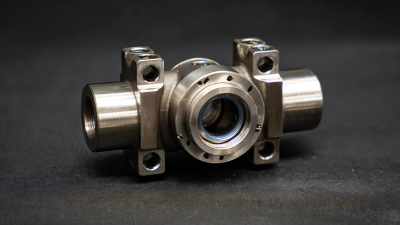

Understanding the various types of isolation valves is crucial for making informed decisions during installation and maintenance. Gate valves, known for their low flow resistance, are preferred in applications where minimal pressure drop is required. Conversely, ball valves provide a tight seal, making them ideal for systems that must be completely shut off. A study by MarketsandMarkets highlights that the increasing emphasis on energy efficiency and the adoption of automated control systems are significantly influencing the growth of the isolation valve market. As industries prioritize reliable and efficient fluid management, the role of these valves becomes increasingly vital.

| Valve Type | Material | Size (Inches) | Pressure Rating (PSI) | Temperature Rating (°F) | Applications |

|---|---|---|---|---|---|

| Ball Valve | Brass | 1/2 - 4 | 600 | -20 to 200 | Residential and Commercial Plumbing |

| Gate Valve | Cast Iron | 2 - 12 | 250 | -20 to 180 | Water Supply and Waste Systems |

| Globe Valve | Stainless Steel | 1 - 8 | 300 | -20 to 450 | Steam and Oil Applications |

| Check Valve | PVC | 1 - 6 | 150 | -10 to 140 | Drainage and Waste Systems |

| Butterfly Valve | Aluminum | 2 - 24 | 200 | -10 to 200 | Water Treatment and HVAC |

| Pressure Relief Valve | Brass | 1/2 - 3 | 150 | -20 to 250 | Boiler Systems and Pumps |

| Solenoid Valve | Plastic | 1/4 - 1 | 100 | -10 to 160 | Automated Systems and Irrigation |

| Float Valve | Copper | 1 - 2 | 125 | -20 to 180 | Water Storage and Tanks |

| Angle Valve | Bronze | 1/2 - 2 | 300 | -20 to 200 | Heating and Cooling Systems |

| Dual Plate Check Valve | Stainless Steel | 2 - 10 | 150 | -15 to 300 | Fire Protection and Water Supply |

When selecting isolation valves for plumbing and industrial applications, several key features should be prioritized to ensure optimal performance and reliability. One crucial factor is the valve type; options such as ball valves, gate valves, and butterfly valves each possess unique characteristics that suit different operational needs. For instance, a report by the Global Valves Market indicates that ball valves account for approximately 40% of the overall market share due to their excellent sealing capabilities and ease of operation, making them ideal for applications requiring quick shut-off.

Another important consideration is the material composition of the isolation valve. Valves made from durable materials like stainless steel or brass are known to withstand high pressure and corrosive environments, contributing to a longer service life. According to a study from Research and Markets, the demand for stainless steel valves is projected to grow by 6.3%% annually, driven by industries such as oil and gas where leakage prevention is paramount. Additionally, compatibility with the specific fluid type (such as water, oil, or gas) is essential to avoid material degradation and ensure safe operation. Operators should also take into account the size and pressure rating of the valve to match the existing plumbing infrastructure effectively.

When it comes to residential plumbing, having reliable isolation valves is essential for maintaining control over your water supply. These valves allow homeowners to shut off the water flow to specific fixtures or areas in the house, making it easier to perform repairs or handle emergencies without disrupting the entire system. Understanding the different types and features of isolation valves can help you select the best options for your plumbing needs.

Among the top choices for residential use are ball valves, gate valves, and globe valves. Ball valves are highly favored for their quick operation and minimal flow resistance, making them ideal for situations where immediate shut-off is necessary. Gate valves, while not as fast, provide a good solution for areas where water supply needs to be controlled with greater precision. In contrast, globe valves offer excellent throttling capabilities for adjusting water flow gradually. When choosing isolation valves, consider factors such as durability, compatibility with your piping system, and ease of access to ensure you have the best options for your home’s plumbing system.

When it comes to heavy-duty applications, selecting the right industrial isolation valve is crucial for ensuring system reliability and operational efficiency. According to a report by Grand View Research, the global industrial valve market size was valued at approximately USD 70 billion in 2022, with a projected CAGR of 6.5% from 2023 to 2030. This growth highlights the increasing demand for robust and efficient isolation valves in industries such as oil and gas, chemical processing, and water treatment.

In heavy-duty applications, isolation valves not only control fluid flow but also provide necessary safety measures to protect equipment and personnel. For example, the American Society of Mechanical Engineers (ASME) recommends the use of resilient wedge gate valves in high-pressure applications due to their reliable sealing capabilities and durability under extreme operational conditions. Additionally, the use of ball valves is gaining popularity for their low flow resistance and ease of automation, making them ideal for dynamic applications that require precise control. Investing in high-quality isolation valves can significantly reduce maintenance costs and enhance system performance in industrial settings.

When it comes to ensuring the longevity of isolation valves, proper installation and regular maintenance play crucial roles. First, during installation, it is imperative to choose the right type of isolation valve suitable for the specific application, whether in plumbing or industrial settings. Ensuring that all connections are secure and correctly fitted will prevent leaks and improve the overall efficiency of the system. Additionally, following the manufacturer's installation instructions and using appropriate tools can minimize the risk of damage during the setup.

Maintenance is equally vital to extend the lifespan of isolation valves. Routine inspections should be performed to check for any signs of wear or corrosion. It is advisable to exercise the valve periodically to ensure smooth operation, as valves that are left inactive for extended periods may become stuck. Furthermore, replacing seals and gaskets at the first sign of wear can prevent significant issues down the line. Keeping the valve clean from any debris and ensuring that any necessary lubrication is applied will also contribute to optimal performance and durability.