In today's rapidly evolving industrial landscape, the importance of hygiene standards cannot be overstated, particularly in sectors such as food processing, pharmaceuticals, and biotechnology. Central to maintaining these standards is the adoption of innovative technologies, among which the sanitary check valve plays a pivotal role. This essential component is designed to prevent backflow, ensuring that fluids remain uncontaminated and processes remain compliant with stringent health regulations. Recent advancements in the design and functionality of sanitary check valves have not only enhanced their performance but have also set new benchmarks for industry hygiene standards. By delving into key statistics and breakthroughs in this field, we can better understand how sanitary check valves are redefining hygiene protocols and contributing to safer and more efficient industrial operations. This exploration will underscore the critical role that these valves play in safeguarding public health and ensuring product quality across various industries.

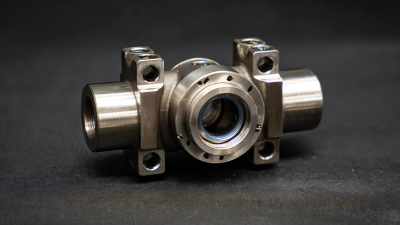

When selecting sanitary check valves, several key features are essential to ensure optimal performance and compliance with hygiene standards. First and foremost, the material of construction plays a critical role. Valves made from stainless steel, particularly grades like 316L, are preferred due to their corrosion resistance and ability to withstand high temperatures. This not only maintains the integrity of the fluids being transported but also minimizes contamination risks.

Another important feature to consider is the valve design. Sanitary check valves should have a smooth, cleanable interior surface to prevent residue buildup, which can harbor bacteria. Look for designs that facilitate easy disassembly and cleaning, such as those that can be fully opened for thorough inspection.

Additionally, consider the sealing mechanism; high-quality elastomers or PTFE seals can ensure leak-proof functionality while maintaining hygiene. Ultimately, selecting a sanitary check valve that combines these critical features will significantly enhance process efficiency and uphold stringent cleanliness standards in industrial applications.

Sanitary check valves play a crucial role in maintaining hygiene standards in various industries, especially in food and pharmaceuticals. Recent innovations in materials used for these valves have significantly enhanced their ability to prevent contamination. Advances in elastomers and polymer composites have led to the development of valves that not only resist the growth of bacteria but also withstand extreme temperatures and chemicals. These materials ensure that valves maintain their integrity, reducing the risk of leakage and contamination in critical processes.

Moreover, the incorporation of antimicrobial coatings and specialized finishes further elevates the hygiene performance of sanitary check valves. These innovations help to create surfaces that are less prone to fouling, thus simplifying cleaning and maintenance. The emphasis on using non-toxic, FDA-approved materials also aligns with the industry’s increasing regulatory demands for safety and hygiene. As these materials evolve, industries can rely on smarter, safer, and more efficient sanitary check valves that contribute to overall process integrity and product quality.

| Dimension | Metric | Value |

|---|---|---|

| Material Types | Innovative Materials | Stainless Steel, PTFE, EPDM |

| Hygiene Standard Compliance | Regulatory Standards | FDA, EHEDG, 3-A Sanitary |

| Maximum Operating Pressure | Pressure Rating | 10 bar |

| Temperature Range | Operating Temperatures | -10°C to 120°C |

| Installation Type | Mounting Options | Welded, Flanged, Threaded |

| Lifecycle Cost | Total Cost of Ownership | Reduced by 20% with innovative designs |

| Market Growth Rate | Annual Growth Rate | 5% CAGR (2023-2028) |

Sanitary check valves play a critical role in ensuring the safety and hygiene of processes within the food and pharmaceutical industries. These valves are designed to prevent backflow, which is essential in maintaining the purity of products. In environments where contamination can have serious repercussions, such as food processing plants and pharmaceutical manufacturing facilities, the use of high-quality sanitary check valves is not just a regulatory requirement but a fundamental component of operational integrity.

Sanitary check valves play a critical role in ensuring the safety and hygiene of processes within the food and pharmaceutical industries. These valves are designed to prevent backflow, which is essential in maintaining the purity of products. In environments where contamination can have serious repercussions, such as food processing plants and pharmaceutical manufacturing facilities, the use of high-quality sanitary check valves is not just a regulatory requirement but a fundamental component of operational integrity.

Recent innovations in sanitary check valve design have significantly improved their performance and reliability. Advances such as enhanced sealing mechanisms and the use of advanced materials are contributing to stricter hygiene standards. These innovations not only help in maintaining product integrity but also facilitate ease of cleaning and maintenance, thus minimizing downtime. As industries continue to evolve, the integration of state-of-the-art sanitary check valves becomes increasingly vital in meeting both market demands and regulatory compliance.

Maintaining and inspecting sanitary check valves is crucial for ensuring optimal performance in various industries, particularly those dealing with food processing and pharmaceuticals. Regular maintenance routines should include visual inspections for any signs of wear or damage, as well as functional tests to ensure that the valve closes correctly without any leaks. The frequency of these inspections often depends on the specific application and operating conditions, but a proactive approach can prevent costly downtime and maintain product integrity.

In addition to routine maintenance, it's important to implement a cleaning protocol that adheres to hygiene standards. This may involve utilizing specialized cleaning agents that are compatible with the materials of the check valves. Technological innovations, such as the use of non-corrosive materials and advanced sealing solutions, can also enhance the longevity and reliability of these valves. By effectively maintaining and inspecting sanitary check valves, industries can not only comply with hygiene regulations but also enhance overall operational efficiency.

This bar chart illustrates the performance metrics of sanitary check valves, displaying key factors such as flow rate, pressure drop, inspection frequency, and failure rate. These metrics are crucial for understanding the operational efficiency and hygiene standards in various industrial applications.

Emerging technologies are significantly influencing the design and functionality of sanitary check valves, a crucial component in maintaining hygiene and preventing contamination in various industries, particularly food and pharmaceuticals. Innovations such as 3D printing and advanced materials science are enabling the creation of check valves that are not only more durable but also easier to clean and maintain. These technologies allow for the development of complex geometries that enhance fluid flow while minimizing stagnant areas where bacteria could proliferate.

Additionally, the integration of smart technologies, including IoT sensors, is paving the way for real-time monitoring of valve performance. This capability allows for proactive maintenance, reducing downtime and ensuring compliance with stringent hygiene standards. As industries increasingly prioritize cleanliness and efficiency, these advancements promise to redefine the operational landscape, enhancing both product safety and production efficiency. The future of sanitary check valves, influenced by these emerging technologies, is set to drive significant gains in hygiene and operational effectiveness across various sectors.