In the realm of fluid control systems, the spring loaded check valve has emerged as a crucial component for ensuring efficient and reliable operation. According to a recent market research report by Grand View Research, the global valve market is projected to reach USD 88.6 billion by 2025, with check valves representing a significant share due to their versatility and effectiveness in preventing backflow. The rising demand for energy-efficient systems across various industries further underscores the importance of high-quality components, such as premium spring loaded check valves. Among manufacturers, China's leading producers are not only meeting these demands but are also enhancing global trust through exceptional after-sales service and reduced maintenance costs. This blog explores how leveraging these advantages can lead to improved operational efficiency and reliability in fluid management systems, emphasizing the significance of choosing the right spring loaded check valve for diverse applications.

In the pursuit of optimal performance in various industrial applications, selecting a reliable manufacturer for premium spring loaded check valves becomes paramount. According to recent industry reports, well-designed spring loaded check valves are essential for ensuring efficient fluid management and preventing backflow, which can lead to system failures. When evaluating manufacturers, factors such as material quality, flow characteristics, and the ability to handle diverse pressures should be prioritized. Premium check valves are often engineered to withstand extreme conditions, which enhances their reliability over time.

Moreover, the global market for check valves is projected to witness a significant growth rate, underscoring the importance of choosing manufacturers that adhere to international standards. Manufacturers with stringent quality control measures, a robust supply chain, and advanced engineering capabilities will contribute to the overall performance and longevity of the valves. As seen in industries ranging from HVAC systems to automotive applications, the right valve can lead to improved energy efficiency and substantial cost savings. This makes it imperative for businesses to partner with industry leaders that instill confidence and trust in their products.

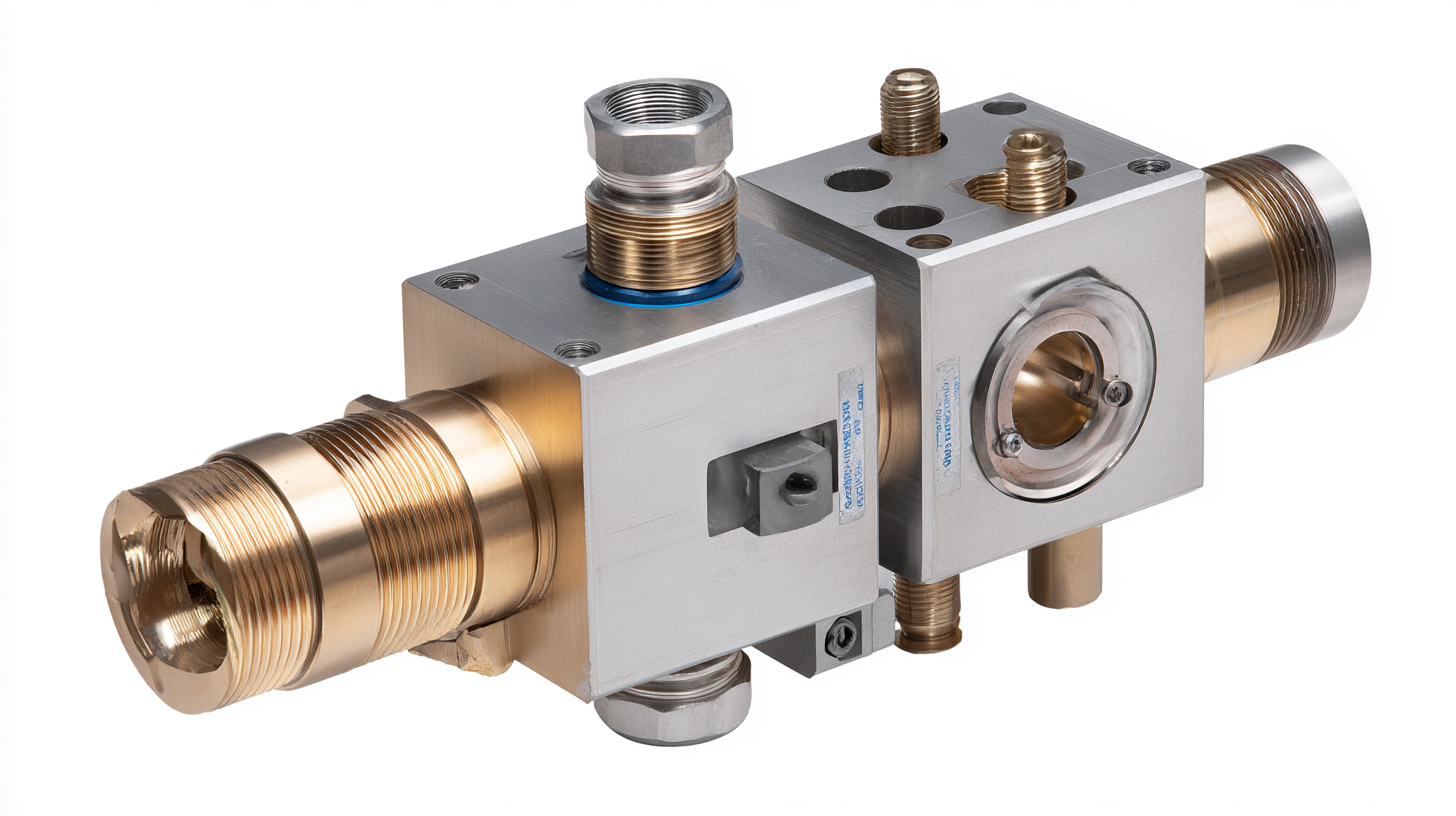

When evaluating check valve manufacturing processes, it's essential to focus on several key features that ensure premium quality and reliability. First and foremost, precise engineering and advanced manufacturing techniques play pivotal roles in the overall performance of check valves. Leading manufacturers employ state-of-the-art machinery and computerized systems to guarantee that each valve meets stringent specifications. This attention to detail minimizes the likelihood of defects and ensures that the valves function optimally under various pressure conditions.

Another critical feature is the selection of high-grade materials. A reputable manufacturer will prioritize durability by using corrosion-resistant alloys and robust seals. This choice not only extends the lifespan of the valves but also maintains their integrity in demanding environments. Additionally, thorough testing and quality assurance protocols are vital. Manufacturers should conduct extensive inspections during each stage of the production process, including pressure testing and leak detection, to ensure that every valve performs to global standards. These stringent guidelines not only foster trust among international clients but also establish the manufacturer as a leader in the industry.

In recent years, the demand for high-quality spring loaded check valves has soared globally, driven by industries that prioritize safety and efficiency. As one of China's leading manufacturers, attention to stringent quality control standards has become paramount. This ensures that each valve meets the exact specifications needed to withstand critical operational conditions. Rigorous testing protocols, from material selection to final product assessment, play a crucial role in building trust with international customers.

The manufacturing process involves a comprehensive quality management system that adheres to internationally recognized standards, such as ISO certification. This includes regular audits, performance evaluations, and adherence to best practices in production. By employing state-of-the-art technology and skilled technicians, manufacturers ensure their valves are not only durable but also reliable under various pressure and temperature conditions. The focus on quality is evident, as manufacturers implement continuous improvement initiatives to adapt to evolving industry demands. Such commitment to quality not only enhances the product's reputation but also solidifies the manufacturer's position in the global market.

| Dimension | Standard Value | Measurement Method | Frequency of Testing |

|---|---|---|---|

| Material Composition | ASTM A351 | Spectroscopy | Per Batch |

| Pressure Test | 150% of Rated Pressure | Hydrostatic Testing | Every 100 Units |

| Leakage Test | No Leakage at Rated Pressure | Air/Water Testing | Each Valve |

| Dimensional Inspection | ±0.02 mm | Caliper Measure | Per Batch |

| Surface Finish | Ra < 1.6 µm | Roughness Tester | Per Batch |

When it comes to manufacturing high-quality check valves, the choice of raw materials is paramount. Premium check valves, especially those produced by China's leading manufacturers, often utilize a combination of stainless steel, brass, and various resilient elastomers. Stainless steel is favored for its corrosion resistance and durability, making it suitable for both high and low-pressure applications. Brass, on the other hand, is known for its affordability and excellent machinability, while elastomers provide flexibility and sealing capability in dynamic environments.

When it comes to manufacturing high-quality check valves, the choice of raw materials is paramount. Premium check valves, especially those produced by China's leading manufacturers, often utilize a combination of stainless steel, brass, and various resilient elastomers. Stainless steel is favored for its corrosion resistance and durability, making it suitable for both high and low-pressure applications. Brass, on the other hand, is known for its affordability and excellent machinability, while elastomers provide flexibility and sealing capability in dynamic environments.

Tip: Always verify the grade of materials used in the check valves, as this can significantly affect their longevity and performance.

Another critical raw material aspect is the importance of quality control during the manufacturing process. Leading manufacturers implement stringent testing and inspections to ensure that each component meets international standards. This reduces the likelihood of defects and ensures that the valves function effectively under various conditions.

Tip: Look for certifications and compliance specifications when sourcing check valves; this can be a reliable indicator of quality and performance.

In today's global marketplace, the importance of certifications and compliance in valve manufacturing cannot be overstated. As a leading manufacturer in China specializing in premium spring-loaded check valves, we understand that meeting international standards is crucial for building trust with clients across the globe. Certifications such as ISO 9001 and CE mark not only validate the quality of our products but also enhance customer confidence in their performance and reliability. Thus, investing in certified processes ensures that our valves consistently meet stringent regulatory requirements.

Tip: When evaluating valve manufacturers, always check for relevant certifications and compliance documents. This not only provides assurance of product quality but also reflects the manufacturer's commitment to industry best practices.

Furthermore, compliance with industry standards aids in minimizing the risks associated with valve failures. It ensures that all materials used are tested and verified, which is essential for applications in critical sectors such as oil and gas, water treatment, and pharmaceuticals. A certified manufacturer implements rigorous quality control processes that contribute to the overall safety and efficiency of their products.

Tip: Look for manufacturers who are transparent about their compliance processes and readily provide documentation. This transparency is a strong indicator of their reliability and dedication to quality assurance.