In today's fast-paced industrial landscape, optimizing system efficiency is paramount. One effective solution that has gained significant traction is the use of pulsation dampeners. According to a report from the Hydraulic Institute, systems equipped with pulsation dampeners can experience up to a 30% reduction in pressure fluctuations, leading to enhanced operational stability and longer equipment life. Furthermore, the Global Market Insights report highlights that the market for pulsation dampeners is expected to witness a CAGR of 5.5% from 2023 to 2030, reflecting their growing importance in improving process efficiency across various sectors. By effectively managing flow variability and minimizing vibration, pulsation dampeners not only contribute to energy savings but also reduce maintenance costs and downtime. Therefore, understanding how to integrate and optimize these devices is crucial for industries looking to enhance their productivity and operational efficiency.

Pulsation dampeners play a critical role in enhancing system efficiency by smoothing out fluctuations in fluid flow. Understanding various key metrics associated with pulsation dampeners is essential for optimizing their performance. The primary metrics include the dampening ratio, volume capacity, and response time. A well-calibrated dampening ratio can significantly reduce pressure spikes, leading to steadier operation and reduced wear on system components. Accurate volume capacity ensures that the dampener can effectively absorb pulsations without risking fluid disruptions or inefficient operation.

Additionally, response time is crucial, as it determines how quickly the dampener reacts to changes in pressure. A faster response time allows for immediate adjustments, maintaining a consistent flow and temperature, which are vital for processes like chemical reactions or energy generation. By analyzing these key metrics, engineers can select appropriate dampeners and adjust system designs for optimal performance, ultimately leading to increased efficiency and reduced operational costs. Understanding the interplay between these metrics enables system improvements that not only enhance performance but also extend equipment lifespan.

This chart illustrates the impact of pulsation dampeners on system efficiency across different metrics. The data reflects average efficiency percentages before and after the implementation of pulsation dampeners in various systems.

Pulsation dampeners play a crucial role in enhancing the efficiency of industrial systems, and their benefits are well-supported by recent industry research. According to the 2025 Employee Benefits Survey, organizations with optimized operational systems tend to experience higher employee satisfaction and retention rates. In industrial applications, pulsation dampeners help mitigate pressure fluctuations, resulting in smoother operations and reduced wear on equipment. This optimization not only extends machinery lifespan but also saves costs on maintenance, as reported by industry reports showing maintenance costs can be reduced by up to 30% when pulsation dampeners are employed.

Moreover, recent analyses indicate that systems utilizing pulsation dampeners can increase output efficiency by approximately 15% to 20%. This significant improvement underscores the value of integrating these devices into various industrial processes. Statistical support further emphasizes that businesses adopting pulsation dampeners experience less downtime, which is vital in maintaining productive operations. In a competitive landscape where efficiency is paramount, the adoption of pulsation dampeners emerges as a foundational strategy for organizations seeking to maximize their operational performance.

Moreover, recent analyses indicate that systems utilizing pulsation dampeners can increase output efficiency by approximately 15% to 20%. This significant improvement underscores the value of integrating these devices into various industrial processes. Statistical support further emphasizes that businesses adopting pulsation dampeners experience less downtime, which is vital in maintaining productive operations. In a competitive landscape where efficiency is paramount, the adoption of pulsation dampeners emerges as a foundational strategy for organizations seeking to maximize their operational performance.

Optimizing your system's efficiency is crucial for reducing operational costs, and one effective method is through the proper sizing of pulsation dampeners. According to the Hydraulic Institute's latest report, improperly sized pulsation dampeners can lead to energy losses of up to 30%. By ensuring that dampeners are accurately sized to match system specifications, companies can significantly minimize these losses and enhance overall performance.

To maximize efficiency with pulsation dampeners, it’s essential to conduct a thorough analysis of your system's flow rates, pressures, and pulsation characteristics before selection. This assessment allows for selecting the correct size and type of dampener, which not only optimizes energy consumption but also extends the lifespan of pumps and associated equipment.

**Tips:**

1. Regularly monitor your system's performance metrics to identify fluctuations in pressure that may indicate an inadequate dampening solution.

2. Consult with a specialist to determine the precise requirements based on your system’s unique demands; this can yield substantial long-term savings.

| System Type | Pulsation Dampener Size (inches) | Energy Savings (%) | Annual Cost Savings ($) |

|---|---|---|---|

| Hydraulic Pump System | 4 | 25 | $1,500 |

| Air Compressor System | 6 | 30 | $2,200 |

| Chemical Processing | 5 | 20 | $1,200 |

| Water Treatment Facility | 7 | 28 | $1,800 |

| Food Processing Plant | 8 | 22 | $1,600 |

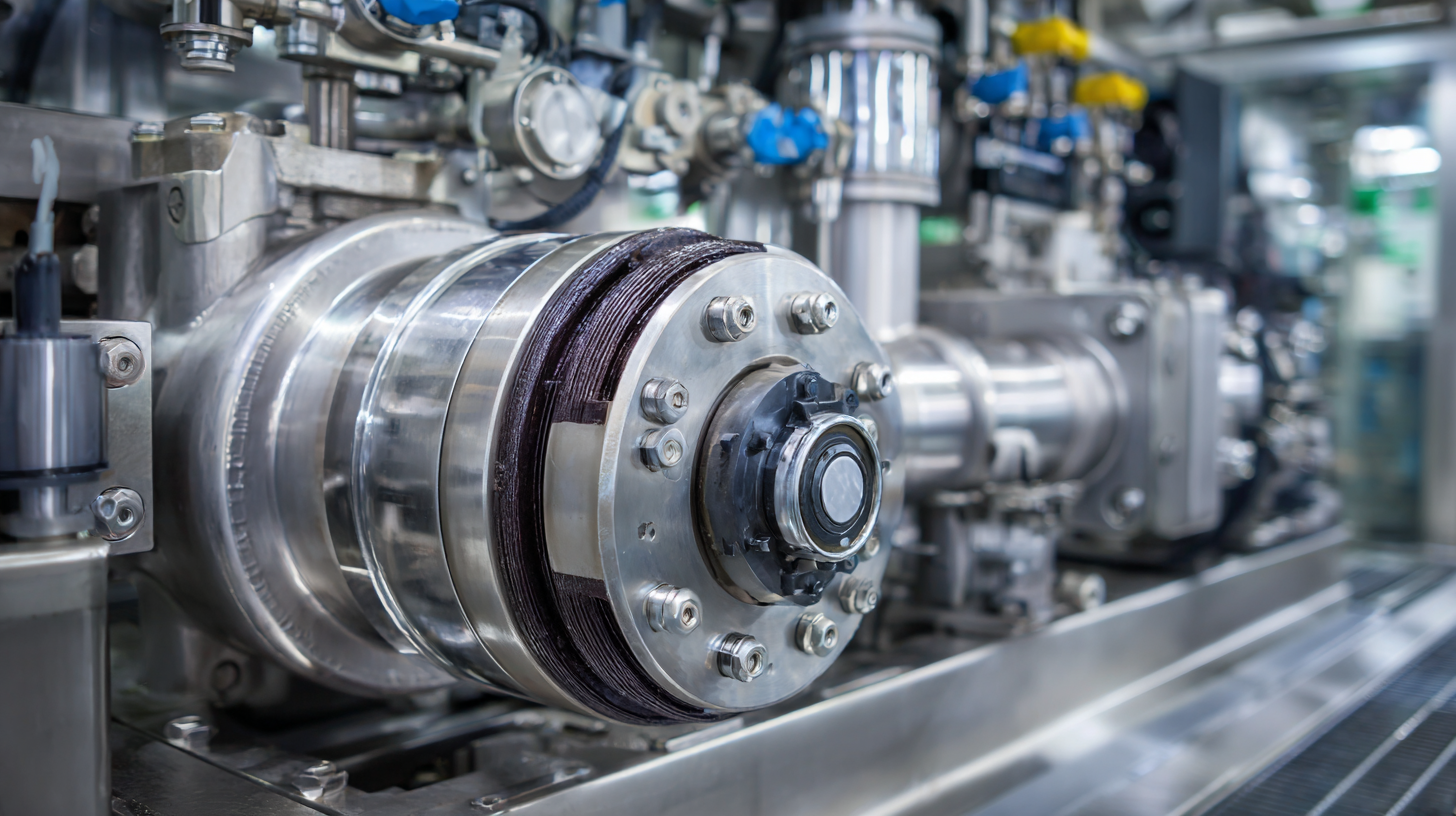

Pulsation dampeners are increasingly recognized for their pivotal role in enhancing system efficiency across various industries. A study conducted by the Hydraulic Institute highlights that implementing pulsation dampeners can reduce pressure fluctuations by up to 95%, leading to smoother operation and reduced wear on equipment. In the oil and gas sector, for instance, companies that integrated these devices reported a 30% decrease in maintenance costs and a 15% increase in operational uptime, demonstrating direct financial benefits alongside enhanced system reliability.

Pulsation dampeners are increasingly recognized for their pivotal role in enhancing system efficiency across various industries. A study conducted by the Hydraulic Institute highlights that implementing pulsation dampeners can reduce pressure fluctuations by up to 95%, leading to smoother operation and reduced wear on equipment. In the oil and gas sector, for instance, companies that integrated these devices reported a 30% decrease in maintenance costs and a 15% increase in operational uptime, demonstrating direct financial benefits alongside enhanced system reliability.

In the pharmaceutical industry, where precision is paramount, pulsation dampeners have shown to minimize product contamination risks related to pressure spikes and fluctuations. According to a report by the American Institute of Chemical Engineers, the use of these devices contributed to a 20% improvement in the consistency of dosage formulations in production lines. This efficiency not only elevates product quality but also ensures compliance with stringent regulatory standards, further underscoring the critical role of pulsation dampeners in optimizing system performance across diverse applications.

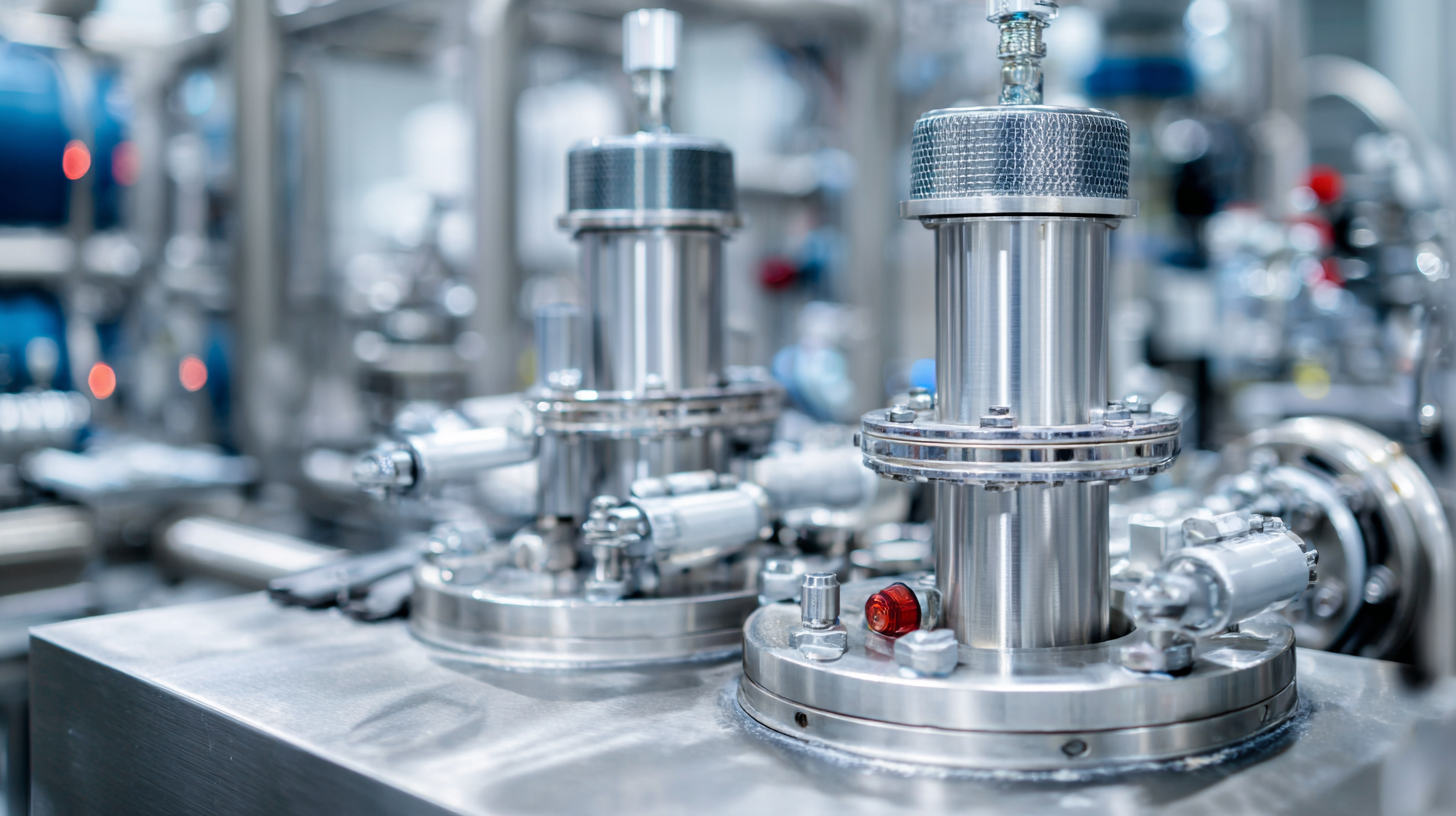

When selecting the right pulsation dampener to enhance system performance, several critical factors must be considered.

Firstly, the type of fluid and its flow characteristics play a significant role. According to a recent report by the Fluid Controls Industry Association (FCIA), systems handling viscous fluids often require dampeners with specialized configurations to effectively mitigate pressure fluctuations. For instance, selecting a dampener that matches the fluid's viscosity can lead to a reduction in pressure spikes by up to 50%, thereby increasing operational efficiency.

When selecting the right pulsation dampener to enhance system performance, several critical factors must be considered.

Firstly, the type of fluid and its flow characteristics play a significant role. According to a recent report by the Fluid Controls Industry Association (FCIA), systems handling viscous fluids often require dampeners with specialized configurations to effectively mitigate pressure fluctuations. For instance, selecting a dampener that matches the fluid's viscosity can lead to a reduction in pressure spikes by up to 50%, thereby increasing operational efficiency.

Another crucial factor is the dampener's material composition. Choosing high-quality materials resistant to corrosion and abrasion can significantly extend the lifespan of the dampener. The American Society of Mechanical Engineers (ASME) indicates that the right material can enhance durability by as much as 40%, reducing downtime due to maintenance. Moreover, the size and volume of the dampener must be tailored to the specific system demands; studies show that an improperly sized dampener can lead to inadequate performance, negating the benefits of the investment. Hence, it's vital to assess the unique requirements of your system to ensure optimal performance through precise selection.