A safety relief valve is a critical component in maintaining pressure control within various industrial systems. Designed to prevent the excessive buildup of pressure, this valve plays an essential role in protecting equipment and ensuring safe operational conditions. The importance of a safety relief valve cannot be overstated, as it safeguards both personnel and property from the potentially catastrophic consequences of overpressure scenarios.

Understanding how a safety relief valve operates is fundamental for engineers and safety professionals alike. When the pressure within a system exceeds the pre-set limit, the safety relief valve automatically opens, allowing excess pressure to escape. This process not only prevents damage to equipment but also helps maintain the integrity of the entire system. The automatic response of the valve to changing pressure levels exemplifies the crucial role of technological advancements in enhancing safety measures in various industries.

In this article, we will delve deeper into the functionality of safety relief valves, exploring their design, application, and significance in pressure control. By gaining insight into how these valves work, we can appreciate their vital contribution to industrial safety and efficient operations.

A safety relief valve is a crucial component in pressure systems, designed to protect equipment and personnel from the dangers of overpressure. By allowing excess pressure to escape when it reaches a predetermined threshold, these valves play a vital role in maintaining system integrity and operational safety. They are commonly used in applications ranging from industrial machinery to residential hot water systems, ensuring that pressure levels remain within safe limits and preventing potentially catastrophic failures.

The importance of safety relief valves cannot be overstated. In the event of a pressure surge, these valves act as the first line of defense, releasing gas or liquid to prevent dangerous conditions that could lead to explosions or equipment damage. Their reliable operation and quick response times are essential for the safe functioning of various systems, making them indispensable in industries such as manufacturing, oil and gas, and chemical processing. Overall, safety relief valves are integral to maintaining safe and efficient operations in environments where pressure control is critical.

| Parameter | Description | Importance |

|---|---|---|

| Type | Spring-loaded valve | Prevents pressure buildup |

| Set Pressure | The pressure at which the valve opens | Crucial for system safety |

| Material | Commonly stainless steel | Enhanced durability and resistance |

| Installation Location | Near the pressure source | Immediate pressure relief |

| Maintenance | Regular inspection required | Ensures reliability and safety |

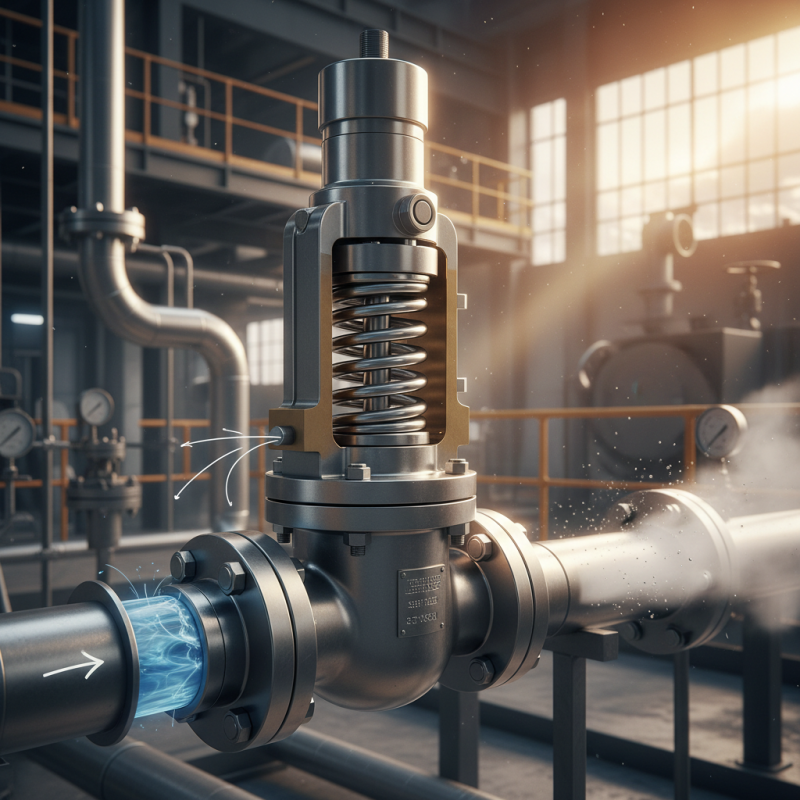

Safety relief valves play a crucial role in maintaining pressure control across a variety of industrial applications. These valves operate based on a straightforward principle: they are designed to automatically vent excess pressure when it exceeds a predetermined limit, thereby preventing potential equipment failure or catastrophic events. The working mechanism typically involves a spring-loaded design where the force exerted by the spring counteracts the pressure in the system. When the internal pressure surpasses the set pressure, the valve opens, allowing fluid to escape until the pressure returns to a safe level, after which the valve resets itself.

Research indicates that the correct sizing and selection of safety relief valves are critical to ensuring optimal functionality and safety. According to industry standards, it is recommended that safety relief valves be sized to handle at least 10% more than the system's expected maximum flow rate to accommodate sudden surges in pressure. Failure to properly size these devices can lead to potential overpressure scenarios, which can result in significant damage; estimations suggest that equipment failure due to inadequate pressure control can cost industries billions annually. Additionally, regular maintenance and testing of these valves are essential practices advocated by safety regulations to guarantee their effectiveness in real-time operations, ensuring that industries can function reliably without the risk of pressure-related incidents.

This bar chart illustrates the pressure levels at different operational states of a safety relief valve. The values represent the pressure measured in psi: normal operation at 100 psi, minor overpressure at 120 psi, major overpressure at 150 psi, and system failure at 180 psi. Understanding these levels helps in evaluating the functioning of safety relief valves in pressure control systems.

Safety relief valves are crucial components in pressure control systems, designed to protect equipment and personnel from overpressure scenarios. The construction of these valves typically includes several key components that work together to ensure efficiency and reliability during operation. Among the primary elements are the valve body, which houses the internal mechanisms; the spring, which provides the necessary force to keep the valve closed until the set pressure is reached; and the disc or poppet, which opens to release excess pressure when needed.

The design features of safety relief valves are equally important, as they influence the valve's performance and suitability for different applications. Common design characteristics include the type of actuator mechanism—spring-loaded or pilot-operated—each catering to specific operational requirements. The discharge outlet is also a vital feature, designed to direct the released pressure safely away from sensitive areas. Additionally, materials used in the construction must withstand the operational environment, ensuring durability and long-lasting performance. By understanding these components and design features, one can appreciate the essential role of safety relief valves in maintaining safe pressure levels in various industrial settings.

Safety relief valves (SRVs) are critical components in industrial systems, designed to prevent overpressure situations that could lead to catastrophic failures. The implementation and maintenance of these valves are governed by stringent industry standards and regulations to ensure operational safety. Regulations such as ASME BPVC Section VIII and API RP 520 provide comprehensive guidelines regarding the design, testing, and installation of safety relief valves. According to the American Society of Mechanical Engineers (ASME), over 30% of pressure-related incidents in industrial settings are linked to valve failures, emphasizing the importance of adhering to established standards.

Additionally, the Occupational Safety and Health Administration (OSHA) mandates compliance with specific safety protocols that include periodic testing and calibration of safety relief systems. The National Board of Boiler and Pressure Vessel Inspectors recommends that these valves be inspected at least annually to ensure their reliability and performance. Data from industry reports indicate that proper adherence to these standards can reduce the likelihood of pressure-related accidents by up to 80%, showcasing the vital role these regulations play in industrial safety. In summary, compliance with established industry standards is essential for the effective functioning of safety relief valves and the overall safety of industrial operations.

Safety relief valves play a crucial role in various industries by ensuring the protection of equipment and personnel against overpressure conditions. These valves are widely used in sectors such as oil and gas, chemical processing, and power generation. In oil and gas installations, safety relief valves are employed to manage the pressure in pipelines and storage tanks, preventing hazardous explosions or leaks that could occur due to uncontrolled pressure build-up. Similarly, in chemical plants, they safeguard reactors and distillation units by venting excess pressure, thereby maintaining safe operational parameters.

Moreover, the application of safety relief valves extends to the water and wastewater treatment industry, where they help regulate pressure in pumping stations and tanks. These valves not only protect infrastructure from damage caused by surges but also ensure the safety of personnel working in potentially dangerous environments. In power generation, especially in steam systems, safety relief valves are essential for preventing boiler explosions, a critical safety concern that underscores their importance across various applications. By automatically releasing pressure, these valves maintain a safe operating environment, contributing significantly to industrial safety and efficiency.