The 2025 China Import and Export Fair, often referred to as the Canton Fair, is poised to showcase cutting-edge innovations in various sectors, including the critical field of isolation valves. As industries increasingly emphasize safety and operational efficiency, the isolation valve market is projected to experience substantial growth, with a report by MarketsandMarkets anticipating a rise from $5.1 billion in 2020 to $7.2 billion by 2025, reflecting a compound annual growth rate (CAGR) of 7.3%. This surge is driven by heightened demand in oil and gas, water treatment, and chemical manufacturing sectors, where isolation valves play a pivotal role in controlling flow and maintaining system integrity. At the 2025 Fair, attendees will have the opportunity to explore the latest advancements in isolation valve technology, highlighting innovations that address industry challenges and enhance safety protocols.

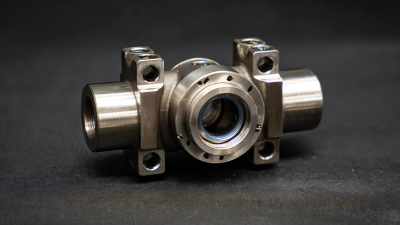

The 2025 China Import and Export Fair has emerged as a pivotal platform for showcasing innovative trends in isolation valve design. As industries evolve, the demand for advanced isolation valves that ensure safety and efficiency in fluid control systems has surged. This year's exhibition highlights cutting-edge technologies such as automated isolation valves, which offer improved precision and responsiveness. Additionally, designers are focusing on creating lighter, more durable materials that enhance the performance and longevity of these essential components.

The 2025 China Import and Export Fair has emerged as a pivotal platform for showcasing innovative trends in isolation valve design. As industries evolve, the demand for advanced isolation valves that ensure safety and efficiency in fluid control systems has surged. This year's exhibition highlights cutting-edge technologies such as automated isolation valves, which offer improved precision and responsiveness. Additionally, designers are focusing on creating lighter, more durable materials that enhance the performance and longevity of these essential components.

Tips for attending the fair: Be proactive in engaging with exhibitors to gain insights into the latest innovations. Consider attending workshops or presentations that focus on emerging technologies in valve design, as they provide valuable knowledge and networking opportunities. Another tip is to take notes on the various products you encounter; this will help you compare features and benefits later on.

The trend towards integrating smart technology in isolation valves is also noteworthy. With the rise of Industry 4.0, manufacturers are implementing IoT capabilities that allow for real-time monitoring and control. This not only boosts safety but also contributes to more efficient maintenance practices. Visitors to the fair will find a range of solutions that cater to diverse industrial needs while promoting

sustainability and operational excellence.

The demand for isolation valves in industrial applications is witnessing significant growth, driven by advancements in technology and the increasing focus on safety and efficiency. As industries look to enhance operational reliability, the role of isolation valves becomes more critical in various sectors, including oil and gas, water treatment, and manufacturing. The 2025 China Import and Export Fair offers a strategic platform to showcase innovative isolation valve solutions designed to meet these evolving industrial needs.

Market analyses indicate that the isolation valve segment is poised for robust expansion, with a rising emphasis on automated and remotely controlled systems that enhance safety measures. Innovations in valve designs and materials are also contributing to their growing application in harsh environments, further fueling market growth. As businesses adapt to the challenges posed by fluctuating market conditions, the integration of smart technologies within isolation valves is likely to present new opportunities for manufacturers, ensuring they remain competitive in this dynamic landscape.

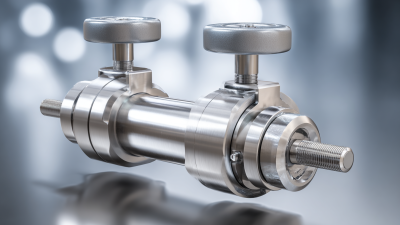

The 2025 China Import and Export Fair is set to showcase groundbreaking technological advancements in the field of isolation valves, particularly focusing on smart isolation valves. Recent industry reports indicate that the global smart valve market is projected to reach USD 12.98 billion by 2027, growing at a CAGR of 6.7% from 2020. This surge in demand highlights the significant role smart isolation valves play in enhancing operational efficiency within various sectors, including oil and gas, water management, and manufacturing.

Smart isolation valves equipped with IoT capabilities allow for real-time monitoring and automated control, thereby minimizing the risk of leaks and improving safety protocols. A report by Markets and Markets estimates that the adoption of IoT in process automation can enhance operational efficiency by up to 25%. Furthermore, these innovations contribute to predictive maintenance, reducing downtime and maintenance costs by potentially 30%, as reported by a study from the International Society of Automation. As stakeholders gather at the fair, the insights gained into these advanced technologies will undoubtedly shape future strategies in valve management and operation.

| Feature | Description | Impact on Efficiency | Market Trend |

|---|---|---|---|

| Remote Monitoring | Allows operators to monitor valve status and parameters in real time. | Enhances quick decision-making and reduces downtime. | Increasing demand for automation in the industry. |

| Smart Sensors | Integrated sensors that detect flow rates and pressure changes. | Improves safety by preventing overpressure incidents. | Growing focus on safety compliance regulations. |

| AI Algorithms | AI-driven analytics to predict maintenance needs. | Significantly reduces maintenance costs and unplanned outages. | Increased interest in predictive maintenance solutions. |

| Energy Efficiency | Designs that minimize energy loss during operation. | Lowers operational costs and promotes sustainability. | Market shift towards eco-friendly technologies. |

| Modular Design | Interchangeable parts for easy maintenance and upgrades. | Reduces turnaround time for repairs and replacements. | Rising demand for customizable solutions in manufacturing. |

The 2025 China Import and Export Fair presents a remarkable opportunity to delve into sustainability within the valve manufacturing sector. As industries increasingly prioritize eco-friendly practices, valve manufacturers are showcasing their latest innovations aimed at reducing environmental impact. From biodegradable materials to energy-efficient production methods, the expo is set to reveal how the valve industry is responding to the global call for sustainability.

One exciting development is the introduction of valves made from recycled materials, which not only conserves resources but also minimizes waste. Additionally, manufacturers are investing in technology that enhances the durability and lifespan of valves, ultimately resulting in lower energy consumption and fewer replacements. These advancements will not only benefit the environment but also provide long-term cost savings for businesses.

**Tips:** When attending the expo, look for exhibitors who highlight their sustainability credentials. Engage with them to understand their practices and consider how such innovations could be integrated into your operations. Additionally, take note of how eco-friendly products are marketed; this can inform your own approach to sustainability in your business initiatives.

At the 2025 China Import and Export Fair, the spotlight on isolation valves will highlight their transformative impact across various sectors. As industries prioritize safety and efficiency, innovative isolation valve solutions have been successfully implemented in sectors such as oil and gas, water management, and pharmaceutical manufacturing. According to a report by MarketsandMarkets, the isolation valves market is projected to reach $14.6 billion by 2027, driven by increasing investments in infrastructure and stringent safety regulations.

Case studies from the oil and gas industry exemplify these innovations. The deployment of advanced isolation valves has significantly enhanced safety protocols during maintenance operations. For instance, a leading oil extraction company reported a 30% reduction in downtime after incorporating smart isolation valves equipped with real-time monitoring systems. This not only improved operational efficiency but also demonstrated compliance with environmental standards mandated by global regulatory bodies.

In the pharmaceutical sector, precise and reliable isolation valves are critical to maintaining sterility and preventing contamination. A notable case study illustrated how a pharmaceutical manufacturer adopted automated isolation valves, leading to a 25% increase in production yield. The seamless integration of these valves into existing workflows underscored their role in not just enhancing safety but also driving productivity in highly regulated environments. These examples reflect a growing trend towards innovation in isolation valves, showcasing their benefits across critical industries.