In various industrial applications, the selection of the right components can significantly influence operational efficiency and safety. The ball check valve, known for its simple design and reliable functionality, plays a crucial role in preventing backflow in piping systems. According to a recent report by Global Market Insights, the $1.5 billion by 2026, driven by growing demands in water and wastewater treatment, oil and gas, and chemical processing industries. Despite their advantages, improper selection can lead to significant operational issues such as leaks and pressure drops. Therefore, understanding how to choose the best ball check valve for specific applications is essential. In this blog, we will explore five essential tips to guide you in selecting the ideal ball check valve, while also addressing common problems associated with various types available in the market.

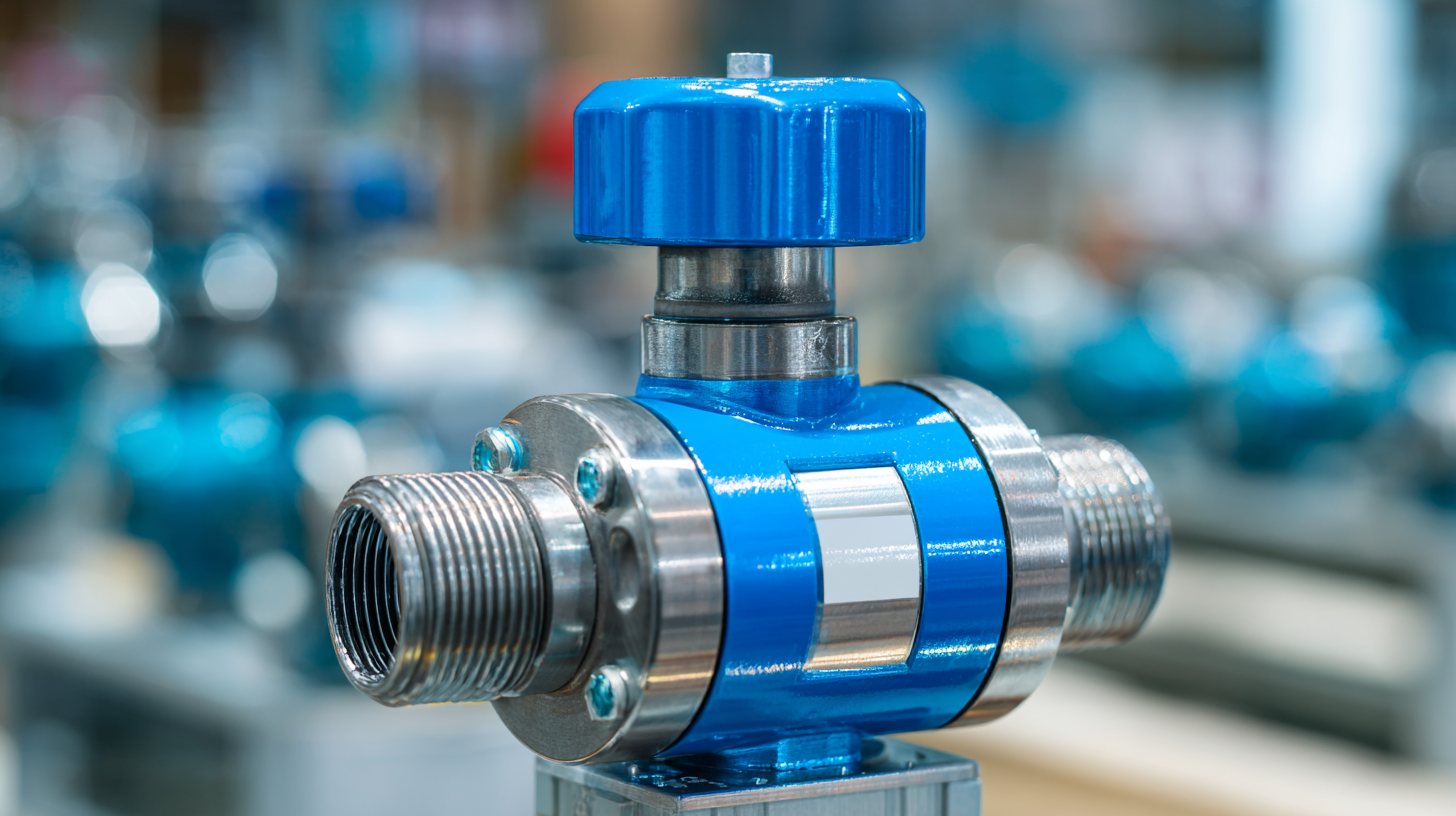

When selecting a ball check valve for your specific application in 2025, understanding the fundamental concepts is crucial. Ball check valves function by allowing fluid to flow in one direction while preventing backflow, primarily through the use of a spherical ball that seals off the flow path when pressure drops. This basic mechanism is essential in industries ranging from water treatment to oil and gas, where maintaining flow direction is paramount for operational efficiency and safety.

As industry trends evolve, manufacturers are focusing on innovations that enhance the reliability and durability of ball check valves. In 2025, we are likely to witness advancements in materials that withstand corrosive environments, as well as designs that facilitate easier maintenance. Additionally, growing environmental concerns are pushing the industry towards more sustainable practices, which could influence the choice of materials and the overall design of these valves. By understanding these trends, engineers and procurement specialists can make informed decisions that align with their operational needs and future-proof their systems.

When selecting a ball check valve for any application, material considerations play a pivotal role in ensuring both longevity and performance. The right materials not only enhance the durability of the valve but also affect resistance to corrosion and other environmental challenges. For instance, choosing high-grade stainless steel or specialized plastics can significantly extend the life of the valve in demanding applications where exposure to harsh chemicals or high temperatures is inevitable.

In the context of modern advancements, materials science is evolving rapidly, with a strong emphasis on sustainability and performance. Much like the ongoing innovations in battery thermal management systems for electric vehicles, which focus on maximizing energy efficiency and extending battery life through superior thermal properties, the choice of materials for ball check valves should also prioritize performance under stress. Left unchecked, poor material selection can lead to failures that might compromise the entire system, akin to the findings from studies on consumer electronics where inadequate thermal management leads to quicker breakdowns. Therefore, evaluating the material composition and its ability to withstand operational conditions is crucial for ensuring optimal performance and longevity in any industrial application.

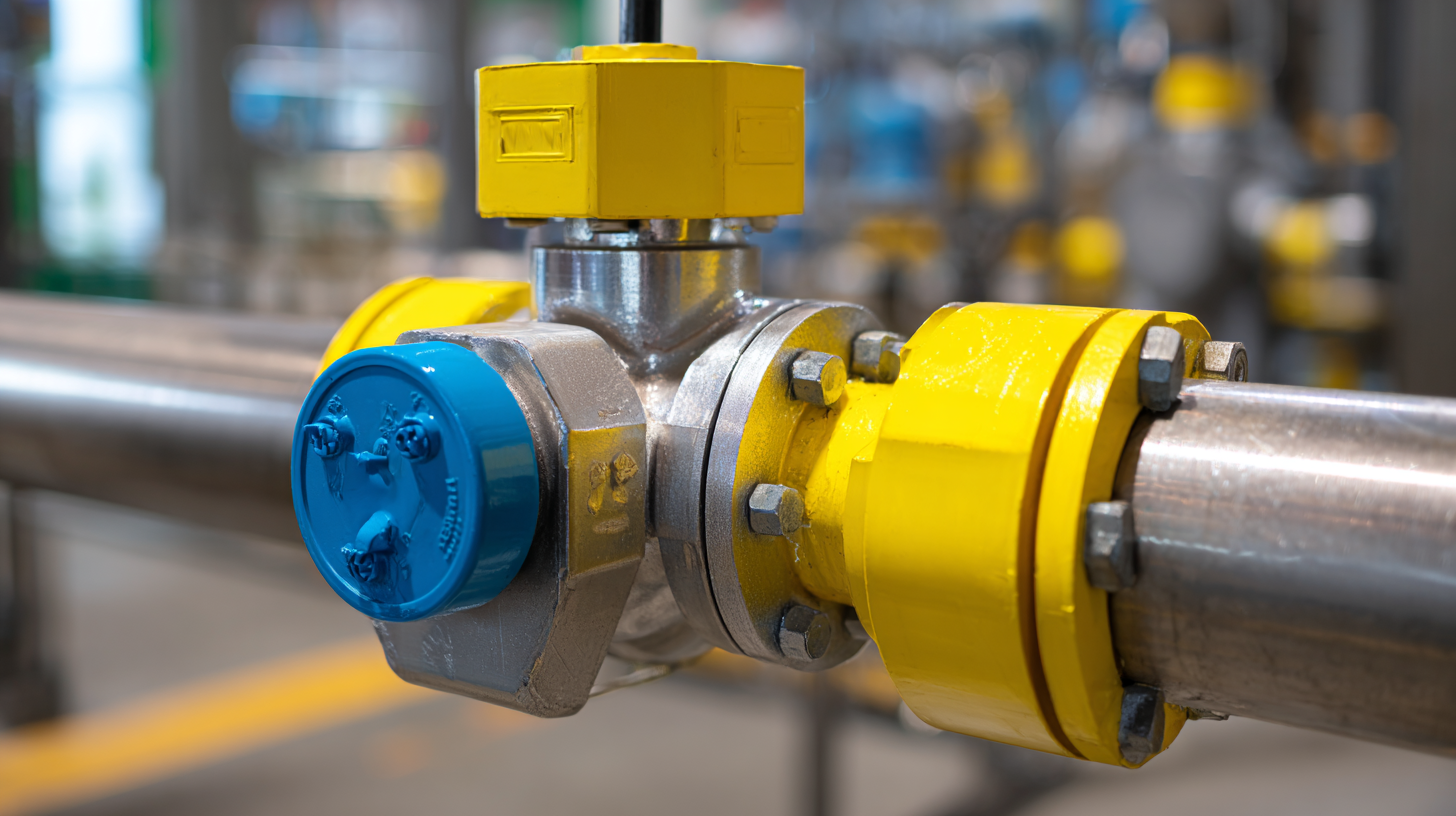

When selecting a ball check valve for your application, proper sizing is crucial to ensure optimal performance. The size of the valve directly impacts the efficiency of fluid flow and pressure drops within a system. An undersized valve can lead to increased resistance and potential surge issues, while an oversized valve may not close effectively under low flow conditions. Calculating the correct valve size, based on the specific requirements of your system, is essential to avoid costly operational disruptions.

Moreover, recent developments in fluid control technologies highlight the importance of precision in valve selection. With the growing implementation of new systems, such as supercritical carbon dioxide pipelines, understanding the dynamic behavior of valves under varying conditions becomes even more significant. By choosing a properly sized ball check valve, you can ensure that your system can efficiently manage the demands of modern industrial applications, improve reliability, and enhance overall energy efficiency. Staying informed about valve technologies and advancements in design will further support the selection process, ensuring that your system operates smoothly and effectively.

This chart illustrates the importance level (on a scale from 1 to 10) of various factors when selecting a ball check valve for different applications. Key considerations include flow rate and material selection, which have the highest importance ratings, followed by pressure drop and size compatibility.

When selecting a ball check valve, understanding pressure and temperature ratings is crucial. According to the 2022 Global Valve Market Study, the industry's shift towards higher efficiency applications necessitates robust components that can withstand extreme conditions. For instance, valves designed for high-pressure systems often exceed 300 psi, while temperature ratings can reach up to 450°F in certain environments. This emphasizes the importance of evaluating the specific requirements of your application to avoid premature failure.

Additionally, different materials used in ball check valves offer varying levels of resistance to pressure and temperature. A report from the American Society of Mechanical Engineers (ASME) highlights that stainless steel valves maintain integrity even under harsh conditions, while plastic variants may suffice in less demanding scenarios. As industries pivot towards sustainable practices by 2025, knowing these differences will ensure that the valves selected enhance efficiency and longevity, reducing maintenance costs and downtime.

When selecting a ball check valve, understanding the innovative features available in modern designs can significantly enhance performance and reliability. One essential feature to consider is the material composition. According to a report from Grand View Research, the global market for ball check valves is expected to reach $3.2 billion by 2027, driven by advancements in materials like high-strength plastics and corrosion-resistant alloys. These materials not only improve the valve's durability but also reduce maintenance costs over the valve's lifespan.

Another feature worth noting is the design of the valve seat and ball. Modern ball check valves often utilize streamlined designs that minimize turbulence and pressure drop. A study published by the American Society of Mechanical Engineers (ASME) indicated that valves with optimized flow paths could improve efficiency by up to 15% compared to traditional designs. Additionally, innovations such as integrated filters and backflow prevention mechanisms are increasingly common, enhancing safety and preventing contamination in sensitive applications. As industries push for higher efficiency and lower operational costs, these modern features are becoming critical in the selection process of ball check valves.

| Tip | Description | Innovative Feature |

|---|---|---|

| 1. Identify Application Requirements | Determine the fluid type, pressure, and temperature to ensure compatibility. | Materials like PVC or stainless steel resistance to corrosion. |

| 2. Check Flow Direction | Ensure that the valve allows flow in the correct direction. | Uni-directional design for preventing back flow effectively. |

| 3. Evaluate Size and Pressure Ratings | Select the appropriate size based on the pipe diameter and pressure ratings. | Compact designs that fit into limited spaces without sacrificing performance. |

| 4. Consider Maintenance Needs | Choose valves that offer easy access for maintenance and repairs. | Removable seats or integral cleaning features. |

| 5. Look for Energy Efficiency | Pick valves that minimize pressure drop to improve energy savings. | Advanced designs that enhance flow rates and reduce energy consumption. |