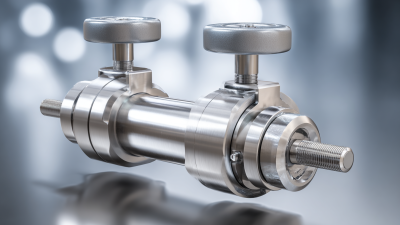

When it comes to plumbing solutions, the choice of materials is critical to ensuring longevity and reliability. The stainless steel ball valve has emerged as a preferred option among industry professionals due to its unparalleled strength and resistance to corrosion. According to a recent report by the Global Ball Valve Market Research Group, the demand for stainless steel ball valves in plumbing applications is projected to grow by over 15% annually, reflecting their increasing acceptance in various industrial and residential settings.

Industry expert Dr. Emily Watson, a leading authority on valve technology, emphasizes the importance of this material in modern plumbing, stating, "Stainless steel ball valves not only provide superior performance but also enhance the safety and sustainability of plumbing systems." With properties such as high-temperature resistance and minimal maintenance requirements, stainless steel ball valves stand out as an essential component for any plumbing project. As customers seek durable and efficient solutions, understanding the advantages of stainless steel ball valves becomes paramount in making informed decisions for plumbing needs.

Stainless steel ball valves are increasingly recognized as a crucial component in plumbing applications due to their durability, reliability, and superior performance. According to a report by MarketsandMarkets, the global ball valve market is projected to reach USD 14.5 billion by 2025, growing at a CAGR of 4.7% from 2020. This significant growth is indicative of the widening acceptance and application of stainless steel ball valves across various industries, including residential and commercial plumbing. Their ability to withstand high pressure and temperature makes them an ideal choice for plumbing systems that may encounter fluctuating conditions.

In plumbing, stainless steel ball valves are particularly valued for their corrosion resistance and longevity. Unlike traditional valve materials, stainless steel can resist pitting, scaling, and rust, which are common issues in plumbing systems exposed to moisture. A study conducted by the American Society of Mechanical Engineers (ASME) highlights that stainless steel valves can last up to 25 years longer than their brass or PVC counterparts, particularly in aggressive environments. This longevity not only reduces the need for frequent replacements but also leads to lower maintenance costs in the long run, thereby enhancing efficiency in plumbing operations.

| Dimension | Material | Pressure Rating | Temperature Range | Applications | Advantages |

|---|---|---|---|---|---|

| 1/2 inch | Stainless Steel 304 | 150 PSI | -20°F to 150°F | Residential Plumbing | Corrosion Resistance |

| 3/4 inch | Stainless Steel 316 | 200 PSI | -50°F to 200°F | Industrial Use | Superior Durability |

| 1 inch | Stainless Steel 304 | 150 PSI | -20°F to 150°F | Water Systems | Easy Maintenance |

| 1 1/2 inch | Stainless Steel 316 | 250 PSI | -50°F to 300°F | Gas Systems | High Pressure Resistance |

| 2 inch | Stainless Steel 304 | 150 PSI | -20°F to 150°F | Heating Systems | Long Lifespan |

When it comes to plumbing applications, the choice of valve material can significantly affect performance, durability, and maintenance requirements. Stainless steel ball valves stand out due to their excellent resistance to corrosion and rust. Unlike brass or plastic valves, stainless steel retains its structural integrity even in harsh environments, such as in salty or humid conditions. This makes stainless steel an ideal choice for both residential and industrial plumbing systems, where exposure to moisture and chemicals can lead to early deterioration of less robust materials.

Furthermore, stainless steel ball valves are known for their longevity and reliability. They can handle higher pressures and temperatures than many alternatives, ensuring optimal performance over time. The smooth operation of a stainless steel ball valve minimizes friction and wear, resulting in less maintenance and a longer service life. Additionally, their hygienic properties make them suitable for plumbing systems that require strict sanitation standards, such as in food processing or healthcare facilities, where the contamination risks must be mitigated.

Stainless steel ball valves are an excellent choice for plumbing systems due to their durability and reliability. One of the key features is their corrosion resistance, which is crucial for systems that deal with water and other liquids that may cause wear and tear over time. This resistance ensures that the valve will maintain its integrity, preventing leaks and maintaining optimal flow rates even in challenging environments. Furthermore, stainless steel ball valves are designed to provide a tight seal, minimizing the risk of drips and ensuring efficient operation.

When selecting suitable valves for your plumbing needs, consider the ease of operation that stainless steel ball valves offer. They typically feature a simple quarter-turn mechanism, allowing for quick and straightforward on/off control. This user-friendly design not only facilitates efficient manual operation but also integrates seamlessly with automated plumbing systems. To enhance your system’s efficiency, ensure that the ball valves are appropriately sized for your pipes to prevent pressure loss.

**Tips:** Regularly inspect your stainless steel ball valves to ensure that they are functioning correctly. Look for any signs of rust or wear, even though stainless steel is resistant to corrosion. Additionally, consider using valve lubricant if you notice any stiffness in movement, which can help maintain smooth operation and prolong the lifespan of your valves.

Stainless steel ball valves are increasingly favored in various plumbing applications due to their durability, corrosion resistance, and operational efficiency. One notable application is in the food and beverage industry, where hygiene and cleanliness are paramount. According to a report by IBISWorld, the food processing industry is expected to grow by 3.5% annually, pushing for robust solutions that can withstand harsh cleaning agents and temperature fluctuations. Stainless steel ball valves are particularly effective in these environments, as they offer smooth internal surfaces that reduce the risk of contamination, while their robust construction can handle high-pressure situations without leaking.

In the chemical processing sector, the use of stainless steel ball valves is also on the rise, owing to their ability to handle aggressive fluids and gases. A 2022 market analysis by Research and Markets highlighted that the chemical processing equipment market is projected to reach over $120 billion by 2025. Stainless steel ball valves play a critical role in these systems, thanks to their resistance to chemical corrosion and capability to maintain flow control with precision. Their ability to operate in extreme temperatures and pressures makes them ideal for processes that require reliability and safety, thereby ensuring uninterrupted production and minimizing downtime.

To ensure the longevity of stainless steel ball valves, proper maintenance is essential. According to industry data from the American Society of Mechanical Engineers (ASME), stainless steel valves can last up to 30 years when maintained properly, benefiting from their corrosion resistance and mechanical strength. Regular inspections should be conducted to check for leaks, surface degradation, or wear and tear. It is crucial to ensure that the operating environments do not expose the valves to extreme conditions outside the specified design limits, as this can significantly shorten their lifespan.

Additionally, lubrication is an important aspect of maintenance. The valve stems should be lubricated periodically with a suitable grease to prevent friction and wear. It is recommended to follow manufacturer guidelines for lubrication intervals. Besides, maintaining the cleanliness of the valve body and surrounding areas will prevent sediment build-up that could impede functionality. A study by the National Association of Corrosion Engineers (NACE) indicated that consistent cleaning and lubrication not only enhance the performance of stainless steel valves but also reduce the risk of catastrophic failures, emphasizing the importance of establishing a routine maintenance schedule.