In the realm of fluid control systems, the wafer butterfly valve has emerged as a popular choice among engineers and system designers. This compact, efficient device is lauded for its ability to regulate the flow of liquids and gases with precision. Unlike traditional valve types, the wafer butterfly valve boasts a unique design that allows for easy installation between flanges, making it an ideal solution for both space-constrained applications and those requiring rapid operational response.

The benefits of wafer butterfly valves extend beyond their installation flexibility. Their lightweight construction and minimalistic design translate to lower material costs and reduced energy consumption, which are essential factors in today’s environmentally-conscious industries. Furthermore, these valves offer exceptional durability and reliability, ensuring long-term performance in various working conditions. The effective sealing capability of wafer butterfly valves contributes to their popularity, preventing leaks and facilitating smooth operations within fluid control systems.

Overall, the benefits of wafer butterfly valves are manifold, making them a preferred option for efficient fluid management. This article will delve into the top ten advantages of wafer butterfly valves, highlighting their significant role in optimizing systems for improved performance and cost-effectiveness.

Wafer butterfly valves have emerged as a preferred choice in various fluid control systems due to their unique design and operational efficiency. One of the primary benefits of wafer butterfly valves is their compact structure, which allows for easier installation between flanges, reducing the need for additional space. According to a report by Global Market Insights, the demand for these valves is projected to grow at a significant rate, reaching an estimated market size of $3.5 billion by 2025, driven largely by their ease of maintenance and lower operational costs.

Furthermore, wafer butterfly valves excel in flow control, providing a linear and minimal resistance path that enables seamless fluid movement. Their ability to handle various types of fluids—including water, oil, and gas—while maintaining durability under high-pressure conditions positions them as a versatile solution in industries such as water treatment and energy. Industry analyses indicate that the use of butterfly valves in these sectors has resulted in efficiency improvements of up to 20%, markedly reducing energy consumption and associated costs.

Another critical advantage of wafer butterfly valves is their quick response time and the ability to achieve near-zero leakage when fully closed. This attribute is essential in applications where precision in flow regulation is paramount. According to a technical study published by the American Society of Mechanical Engineers, the reliability and performance of wafer butterfly valves have been shown to surpass that of conventional valves, making them indispensable for modern fluid control systems in an increasingly efficiency-driven industrial landscape.

| Benefit | Description | Applications |

|---|---|---|

| Compact Design | Wafer butterfly valves take up less space compared to traditional valve types. | Pipelines, HVAC systems |

| Low Pressure Drop | They offer minimal resistance, allowing for better flow rates and efficiency. | Water treatment plants, industrial processes |

| Cost-Effective | These valves are generally more affordable compared to other valve types. | Municipal systems, agriculture |

| Ease of Installation | Wafer butterfly valves can be easily installed between flanges, reducing labor time. | Construction, renovation projects |

| Versatile Material Options | Available in various materials to suit different fluid types and conditions. | Chemical processing, food industry |

| Quick Operation | They provide quick open and close action, enhancing control speed. | Cooling systems, irrigation |

| Minimal Maintenance | Requires less regular maintenance, which saves time and resources. | Pumping stations, oil and gas |

| Good Flow Control | Allows precise control of fluid flow, contributing to process efficiency. | Pharmaceuticals, power generation |

| Lightweight | Their lightweight design makes handling and transportation easier. | Transportation, modular systems |

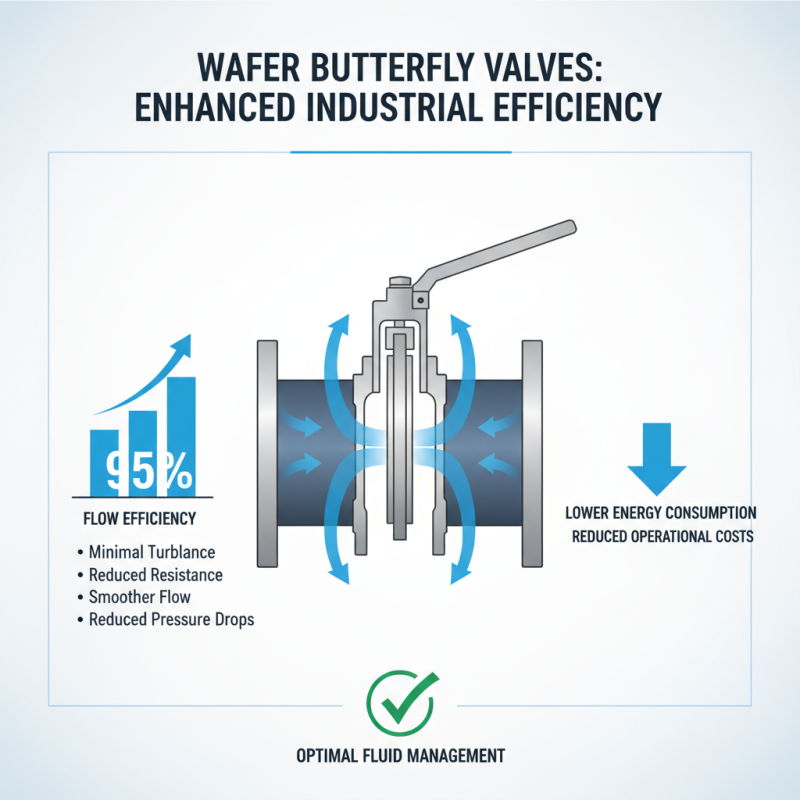

Wafer butterfly valves are gaining popularity in industrial applications due to their enhanced flow characteristics, which can achieve up to 95% efficiency in large piping systems. This efficiency is primarily attributed to the design of the valve, allowing for minimal fluid turbulence and resistance as the fluid travels through the system. The streamlined profile of the valve disc facilitates a smoother flow, reducing pressure drops and improving overall system performance. As a result, industries can benefit from lower energy consumption and reduced operational costs while maintaining optimal fluid management.

In addition to their efficiency, wafer butterfly valves offer versatility in various fluid control applications. Their compact design allows for easy installation in tight spaces without compromising pipeline integrity. This flexibility is crucial in industries such as water treatment, oil and gas, and chemical processing, where maximizing available space and maintaining high fluid flow rates are vital. Moreover, the ability to quickly open and close these valves enhances operational control, making them an ideal choice for applications that require rapid flow adjustments. Ultimately, the integration of wafer butterfly valves can significantly elevate the efficiency and effectiveness of large-scale fluid systems.

Wafer butterfly valves are increasingly recognized for their innovative design, particularly in terms of space efficiency, making them ideal for installations where space is at a premium. Their compact design is a significant advantage, allowing them to fit into tight locations without compromising on performance. This characteristic is especially beneficial in industries such as manufacturing, HVAC, and water treatment, where systems often require valves to be installed in constrained areas.

The design of wafer butterfly valves contributes not only to space-saving but also enhances ease of installation. Their lightweight structure allows for quick handling and maneuvering during setup, further reducing the time and labor costs associated with valve installation. Additionally, the slim profile of these valves means they can integrate seamlessly into existing piping systems, making retrofitting a more straightforward process. Overall, the space-efficient attributes of wafer butterfly valves enable industries to optimize their layouts and improve overall system efficiency.

Wafer butterfly valves are increasingly recognized for their cost-effectiveness in fluid control applications. Their simple design, which consists of a disc that rotates to regulate flow, leads to significantly reduced maintenance needs compared to more complex valve types. This straightforward mechanism not only minimizes wear and tear but also simplifies repair processes, leading to lower operational downtime. As a result, facilities using wafer butterfly valves often experience less frequent replacements, which translates to lower overall expenditure on equipment lifecycle.

In addition to reduced maintenance, wafer butterfly valves also contribute to operational cost savings through improved efficiency. Their lightweight and compact nature allow for easy installation and integration into various systems, reducing labor costs during initial setup. Moreover, their design minimizes pressure loss, resulting in lower energy consumption across the fluid control system. This means that industries employing these valves can enjoy ongoing savings linked to both energy usage and maintenance, making wafer butterfly valves an economically sound choice for efficient fluid control.

Wafer butterfly valves have emerged as a preferred choice for fluid control across a multitude of industries due to their adaptability and performance. According to a report by Global Industry Analysts, the global butterfly valve market is projected to reach approximately $6 billion by 2026, reflecting the increasing demand for efficient fluid management solutions in sectors such as water treatment, chemical processing, and HVAC systems. The compact design of wafer butterfly valves not only facilitates easy installation between flanges but also ensures minimal pressure drop, making them suitable for a wide range of fluids, from water and steam to corrosive chemicals.

In the oil and gas sector, wafer butterfly valves are valued for their ability to handle high flow rates and are frequently utilized in pipelines where space and weight constraints are critical. A 2021 study by the American Society of Mechanical Engineers noted that these valves can operate effectively in temperatures ranging from -20°F to 400°F, demonstrating their versatility in various operational environments. Additionally, their lightweight construction enables reduced support requirements, allowing for significant cost savings in installation and maintenance. This flexibility and efficiency highlight the importance of wafer butterfly valves in modern industrial applications, driving their adoption across diverse fluid control scenarios.