In modern plumbing systems, ensuring efficient water flow and preventing backflow are crucial for maintaining the integrity of your infrastructure. One key component that plays a significant role in achieving this is the non return valve. This ingenious device allows water to flow in one direction while preventing it from reversing, which can lead to a host of plumbing issues. Understanding the top benefits of using non return valves in your plumbing system can help homeowners and professionals alike make informed decisions regarding their plumbing designs and maintenance practices.

Implementing non return valves not only enhances the functionality of plumbing systems but also minimizes the risk of contamination. By preventing backflow, these valves protect your water supply from potential pollutants that could compromise health and safety. Additionally, non return valves contribute to the longevity of your plumbing system by reducing wear and tear caused by reverse flow. Whether you're looking to optimize your existing system or planning for new installations, recognizing the advantages of these valves can lead to more reliable and efficient plumbing solutions.

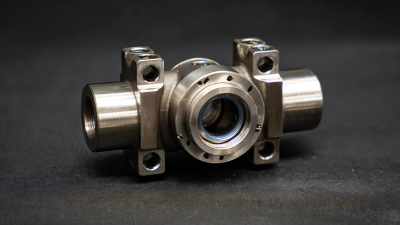

Non-return valves, often referred to as check valves, are critical components in plumbing systems designed to allow fluid to flow in one direction while preventing backflow. These valves operate on a simple yet effective principle: a flap or disc is raised when fluid flows in the intended direction and closes tightly when there is a reverse flow. This functionality is essential in maintaining the integrity of plumbing systems, protecting them from potential damage caused by backpressure or backflow. According to the American Society of Plumbing Engineers (ASPE), proper installation of non-return valves can reduce plumbing failures by up to 30%, highlighting their importance in both residential and commercial applications.

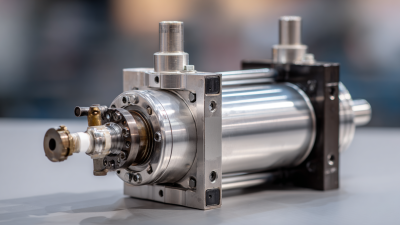

In addition to safeguarding against backflow, non-return valves also enhance system efficiency and performance. By preventing reverse flow, these valves help sustain optimal pressure levels throughout the plumbing system, which is crucial for consistent water delivery and appliance functionality. A report from the International Water Association (IWA) indicates that the installation of non-return valves can save up to 15% in operational costs for water treatment plants by minimizing water loss and enhancing overall system reliability. This data emphasizes how the implementation of non-return valves not only contributes to system longevity but also provides substantial economic benefits, making them an indispensable choice for modern plumbing infrastructures.

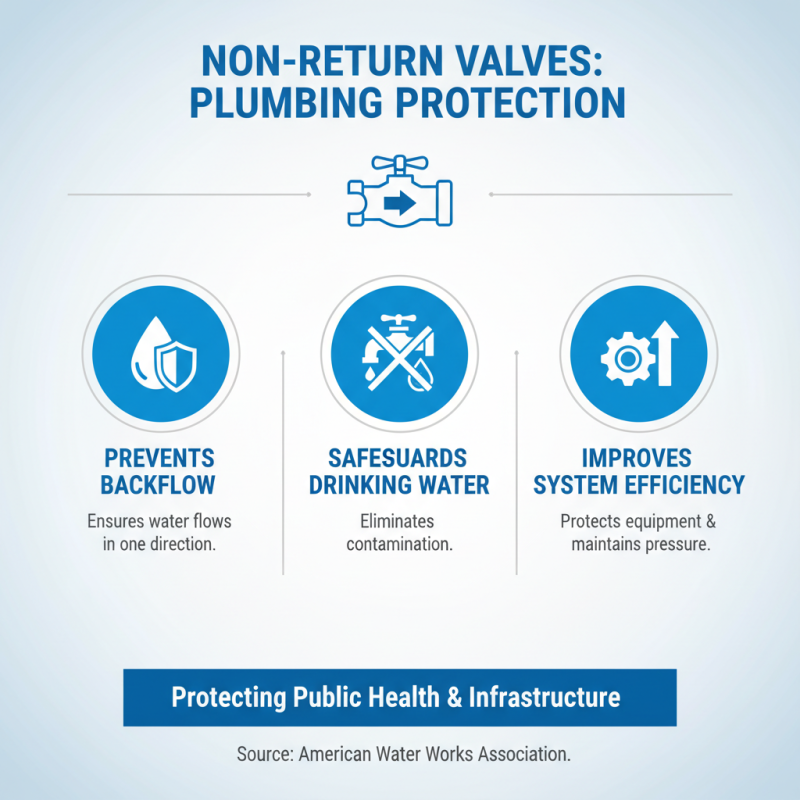

Non-return valves, commonly known as check valves, play a crucial role in maintaining the efficiency and safety of plumbing systems. One of the primary benefits is their ability to prevent backflow, which can lead to contamination of clean water supplies. According to the American Water Works Association, backflow incidents can compromise drinking water systems, emphasizing the importance of implementing non-return valves in residential and commercial plumbing to safeguard public health.

Additionally, non-return valves enhance the operational efficiency of plumbing systems. By ensuring that water flows in one direction, they reduce the strain on pumps and other components which can lead to costly repairs over time. A report by the World Plumbing Council highlights that effective water flow control can increase system longevity and reduce maintenance costs by up to 30%. This not only lowers operational expenses but also contributes to a more sustainable plumbing infrastructure.

Incorporating non-return valves is also beneficial in preventing water hammer, a common plumbing issue that results from sudden changes in water flow direction. According to the Plumbing Engineering and Design Handbook, this phenomenon can cause significant damage to pipes and fixtures, leading to expensive repairs. By mitigating these effects, non-return valves help maintain the integrity of plumbing systems, ensuring reliable performance and safety for users.

Non-return valves, also known as check valves, play a crucial role in enhancing the safety and quality of water in plumbing systems. These devices allow fluid to flow in one direction while preventing backflow, which can introduce contaminants into clean water supplies. According to the American Water Works Association (AWWA), backflow incidents can lead to the contamination of drinking water, posing serious health risks. By strategically incorporating non-return valves into plumbing systems, municipalities can significantly reduce the potential for backflow and ensure that water quality remains uncompromised.

In addition to maintaining water purity, non-return valves contribute to system efficiency. Research published in the Journal of Water Resources suggests that proper installation of these valves can minimize pressure fluctuations, which are often linked to pipe bursts and system failures. Maintaining consistent water pressure not only extends the lifespan of plumbing infrastructure but also aids in reducing the energy consumption associated with water pumping. As a result, this not only protects the environment but also provides cost savings to both consumers and municipal systems alike.

By prioritizing the use of non-return valves, we can promote a safer, more efficient water delivery system that benefits everyone.

Non-return valves play a crucial role in maintaining the integrity of plumbing systems by preventing backflow issues. These valves, often referred to as check valves, allow fluid to flow in one direction and automatically close to prevent reverse flow. This function is essential in numerous applications, from residential plumbing to wastewater systems, where backflow can lead to contamination and poses serious health risks. By ensuring that water and wastewater move in the desired direction, non-return valves help maintain hygiene and system efficiency.

When installing non-return valves, it’s important to consider their placement within the system. For instance, positioning them near the water supply entry points can effectively guard against backpressure from sewer systems. Additionally, regular maintenance checks can prolong the lifespan of these valves and ensure their proper functioning.

Tips: Always inspect non-return valves for any signs of wear or leakage during routine plumbing checks. If you notice any irregularities, it's best to consult a professional to avoid potential backflow incidents. Furthermore, ensure that the valves are adequately sized for your piping system to achieve optimal performance.

When considering the installation and maintenance of non-return valves in plumbing systems, proper practices are essential to ensure their effectiveness. First and foremost, selecting the right size and type of non-return valve is crucial for optimal performance. The valve should match the diameter of the plumbing pipes it is being installed in to prevent flow restriction. It's advisable to install these valves in a horizontal position, as this helps avoid sediment build-up, which can impair functionality. Regular inspections are also vital; checking for any signs of wear or leaks should be part of routine maintenance to address issues before they escalate.

Installation should follow a clear sequence. Begin by ensuring the pipeline is clean and free of debris, which can interfere with the valve's operation. Use proper sealing methods, such as Teflon tape or thread sealant, to prevent leaks at the joints. After installation, testing for proper flow and leakage is necessary. This can be done by observing the valve during operation, ensuring that it opens and closes correctly in response to pressure changes. By adhering to these installation and maintenance tips, you can maximize the lifespan and functionality of non-return valves in your plumbing system, ensuring efficient water flow management.

| Benefit | Description | Maintenance Tip |

|---|---|---|

| Prevents Backflow | Stops water from flowing back into supply lines. | Regularly inspect for leaks around the valve. |

| Enhances System Efficiency | Improves pressure consistency in the system. | Ensure valves are free from debris to function properly. |

| Reduces Water Hammer | Minimizes loud banging noises caused by rapid flow changes. | Check valve integrity to prevent rapid closures. |

| Protects Pumps | Prevents backflow that can harm pump systems. | Inspect pumps and valves regularly for wear. |

| Extends System Lifespan | Reduces wear and tear on plumbing components. | Keep the area around valves clean to prevent rust. |

| Ensures Water Quality | Prevents contamination through stagnant water. | Flush the system regularly to maintain cleanliness. |

| Easy Installation | Can be installed on most pipelines with basic tools. | Follow manufacturer guidelines for proper fitting. |

| Cost-Effectiveness | Reduces long-term repair costs associated with backflow damage. | Invest in quality valves for increased durability. |

| Adaptability | Suitable for various plumbing systems, including residential and industrial. | Assess system needs before selecting valve type. |

| Safety Assurance | Protects against hazardous backflow situations. | Regularly verify operational efficacy of the valve. |