In the realm of industrial applications, the efficiency and effectiveness of machinery play a crucial role in facilitating productivity and operational success. Among the various technologies that have transformed industrial processes, the hydraulic actuator stands out as a pivotal component. Renowned for their robustness and precision, hydraulic actuators harness the power of pressurized fluid to create motion, thereby offering a significant advantage in automating tasks across diverse sectors. Their ability to generate substantial force while maintaining control over speed and position makes them indispensable in modern manufacturing, construction, and material handling operations.

The benefits of incorporating hydraulic actuators into industrial systems are manifold. From enhancing overall system efficiency to providing unparalleled reliability, these devices help businesses to optimize workflows and reduce downtime. Furthermore, their adaptability allows them to be utilized in a wide range of applications, accommodating varied operational requirements. As businesses strive for greater innovation and competitiveness, understanding the top benefits of hydraulic actuators becomes essential for making informed decisions that lead to improved performance and profitability in industrial settings.

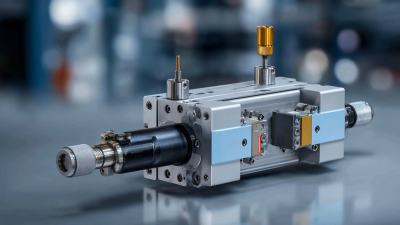

Hydraulic actuators offer significant advantages over pneumatic systems in various industrial applications, primarily due to their superior force capabilities and precise control. One of the standout benefits of hydraulic systems is their ability to generate immense force within a compact design. This allows them to perform heavy-duty tasks without the bulk associated with pneumatic systems, making them ideal for demanding environments such as manufacturing and construction.

The increased pressure that hydraulic systems can withstand enables them to handle more substantial loads, making them suitable for applications where high torque and power are essential.

Moreover, hydraulic actuators provide enhanced accuracy and responsiveness compared to their pneumatic counterparts. This precision is critical in applications that require exact positioning and consistent motion control. Hydraulic systems can easily be adjusted to provide fine-tuned operations, which is particularly beneficial in automated processes where precision is paramount.

Additionally, while pneumatic systems often experience fluctuations in pressure that can lead to inconsistent performance, hydraulic systems maintain stable operation under various conditions. This reliability contributes to increased efficiency and reduced downtime, ultimately leading to lower operational costs in industrial settings.

Hydraulic actuators play a crucial role in industrial applications where precision and control are paramount. In automated processes, the ability to finely tune movements enhances operational efficiency and product quality. Unlike traditional mechanical systems, hydraulic actuators harness the power of pressurized fluid to create smooth and controlled motion. This allows for adjustments in speed and force with remarkable accuracy, which is essential in applications ranging from assembly lines to robotics.

Moreover, the enhanced control precision offered by hydraulic actuators contributes significantly to reducing wear and tear on machinery. By enabling exact positioning and gentle handling of materials, these actuators minimize the risk of damage to components and products. This precision not only results in less downtime due to maintenance but also prolongs the lifecycle of equipment. In environments where consistency is critical, the use of hydraulic technology ensures that each operation adheres to stringent quality standards, ultimately leading to improved productivity and customer satisfaction.

| Benefit | Description | Applications | Control Precision Level |

|---|---|---|---|

| High Force Output | Hydraulic actuators can generate large forces, ideal for heavy lifting. | Construction, Aerospace | High |

| Smooth Operation | Hydraulic systems provide fluid motion, minimizing wear and tear. | Manufacturing, Robotics | Medium |

| Fast Response Time | Quick actuation and responsiveness suitable for dynamic environments. | Automated Production Lines | High |

| Compact Design | Hydraulic actuators can achieve high output in a small size. | Aerospace, Automotive | Medium |

| Energy Efficiency | Hydraulic systems can be more energy-efficient than electric motors. | Plastic Injection Molding, Heavy Machinery | High |

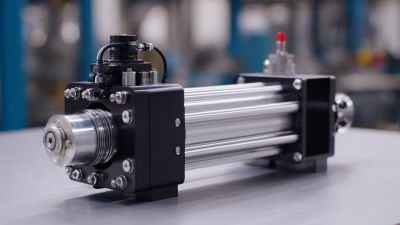

Hydraulic actuators are increasingly recognized for their role in enhancing energy efficiency across various industrial applications. By leveraging the principles of hydraulics, these systems are capable of delivering substantial power and precision while consuming significantly less energy compared to traditional mechanical systems. The core advantage lies in their ability to amplify force without needing extensive machinery, thus reducing the overall energy expenditure associated with operations.

The metrics for energy efficiency in hydraulic systems demonstrate a remarkable reduction in operating costs. Unlike electric actuators that may struggle with overload situations, hydraulic actuators maintain functionality during peak demands, mitigating the risk of energy loss through heat generation. Furthermore, the closed-loop system of hydraulics minimizes leakages and enhances the transfer of energy, ultimately contributing to a more sustainable approach to industrial automation. By investing in hydraulic actuators, industries can not only achieve operational efficiency but also realize long-term savings that result from lower energy consumption and maintenance requirements.

Hydraulic actuators are renowned for their durability and long lifespan, making them an optimal choice for a wide range of industrial applications. One of the most significant advantages of hydraulic actuators is their ability to withstand harsh operating conditions. These actuators are constructed from high-strength materials and are designed to function reliably under extreme temperatures and pressures, ensuring consistent performance over time. This resilience leads to fewer breakdowns and reduced downtime, which is critical in industries where efficiency is paramount.

Maintenance of hydraulic actuators is also relatively straightforward, which adds to their appeal in industrial settings. Routine checks and minor adjustments can often be conducted without the need for extensive downtime or specialized tools. Regular maintenance schedules can significantly extend the lifespan of these actuators, ensuring they remain in peak condition. Furthermore, their inherent design minimizes the risk of wear and tear, allowing them to maintain operational integrity even in demanding applications. Overall, the durability and ease of maintenance associated with hydraulic actuators make them a highly reliable choice for industrial environments focused on longevity and cost-effectiveness.

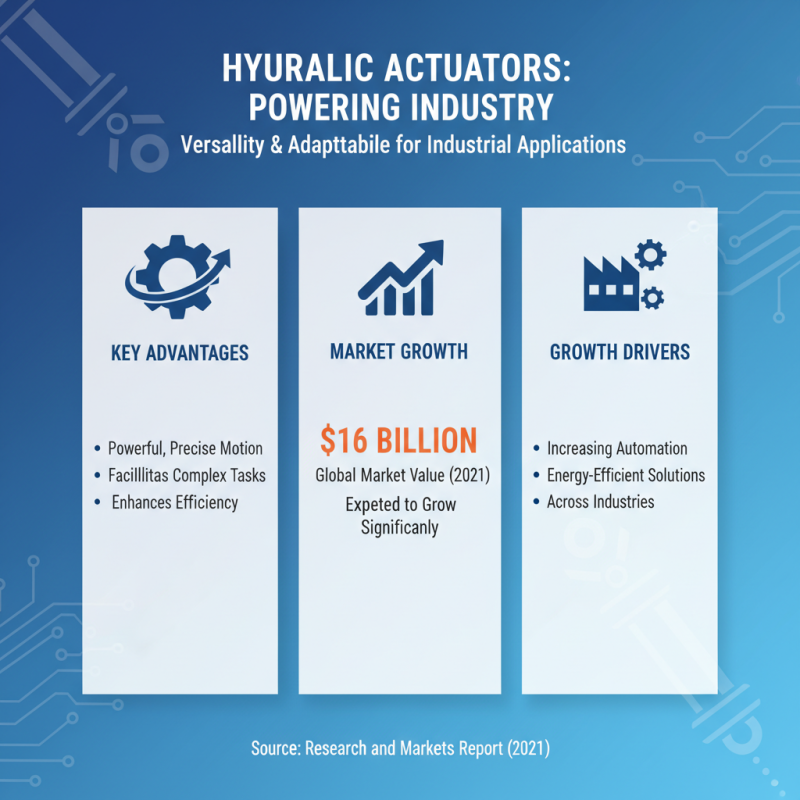

Hydraulic actuators offer remarkable versatility and adaptability, making them a preferred choice for various industrial applications. In sectors ranging from manufacturing to aerospace, the ability to generate powerful and precise motion facilitates complex tasks, enhancing overall efficiency. According to a report by Research and Markets, the global hydraulic actuator market was valued at approximately $16 billion in 2021 and is expected to grow significantly, driven by the increasing demand for automation and energy-efficient solutions across industries.

One of the key advantages of hydraulic actuators is their ability to handle heavy loads with ease, allowing them to be utilized in applications such as construction equipment, automotive assembly lines, and marine vessels. Their robust design can withstand harsh environmental conditions, making them suitable for construction projects where durability is critical. A study by MarketsandMarkets highlights that the construction sector alone accounts for a substantial share of hydraulic actuator usage, emphasizing their role in critical applications like crane operations and excavating machinery.

Additionally, hydraulic actuators are not only efficient but also adaptable to a range of operational requirements. They can function effectively in systems requiring precise control, such as robotics and automated manufacturing lines. The versatility of hydraulic technology supports an increased focus on smart systems, allowing for real-time monitoring and adjustments that improve productivity. As industries continue to evolve, hydraulic actuators remain at the forefront of innovations that drive operational efficiencies.