In the rapidly evolving landscape of modern industrial applications, the quest for enhanced efficiency often leads engineers and decision-makers to reassess their equipment choices. One component that frequently comes under scrutiny is the wafer butterfly valve, a popular and widely used solution for fluid control.

Despite its advantages, such as compact design and ease of installation, the wafer butterfly valve may not always meet the stringent demands of contemporary processes. In this blog, we will explore various alternatives to the wafer butterfly valve, examining advanced options that can provide improved performance, reliability, and sustainability.

We will also share practical tips on how to select the best valve solutions tailored to specific operational needs, ensuring that businesses can maximize efficiency and productivity in their industrial applications.

In the rapidly evolving landscape of modern industrial applications, the quest for enhanced efficiency often leads engineers and decision-makers to reassess their equipment choices. One component that frequently comes under scrutiny is the wafer butterfly valve, a popular and widely used solution for fluid control.

Despite its advantages, such as compact design and ease of installation, the wafer butterfly valve may not always meet the stringent demands of contemporary processes. In this blog, we will explore various alternatives to the wafer butterfly valve, examining advanced options that can provide improved performance, reliability, and sustainability.

We will also share practical tips on how to select the best valve solutions tailored to specific operational needs, ensuring that businesses can maximize efficiency and productivity in their industrial applications.

In today's rapidly evolving industrial landscape, the traditional wafer butterfly valve is facing competition from an array of alternative valve technologies that promise enhanced efficiency and performance. Key among these alternatives are the globe valves, ball valves, and pinch valves, each boasting unique advantages that can cater to various industrial needs. For instance, globe valves provide superior flow regulation due to their design, making them ideal for applications requiring precise control. Meanwhile, ball valves are known for their low flow resistance and quick operation, often preferred in on/off applications where minimal pressure loss is crucial.

When conducting a comparative analysis of these technologies, performance metrics such as flow coefficient (Cv), pressure drop, and response time come into play. Ball valves generally outperform butterfly valves in terms of leakage rates and operational speed, while globe valves shine in applications where flow adjustment is essential. Pinch valves, on the other hand, offer unique benefits in handling slurries and fluids with particulates due to their unobstructed flow path. By understanding these performance metrics, industries can make informed decisions that align with their operational goals, optimizing efficiency while ensuring reliability and safety in their processes.

In modern industrial applications, the efficiency of flow systems significantly influences operational costs. Traditional wafer butterfly valves have been widely utilized, yet their limitations in flow optimization may lead to increased energy expenditure and reduced system performance. According to recent industry reports, businesses are increasingly turning to alternative valve technologies that offer enhanced flow efficiency, potentially lowering energy costs by up to 15%. Innovations in valve design, including the integration of AI-driven controls, allow for real-time adjustments based on operational demands, further improving overall system performance.

As the chemical industry looks towards 2025, focusing on innovation and sustainability, the adoption of advanced technologies such as AI is becoming critical. AI applications not only facilitate predictive maintenance, reducing downtime, but also help in optimizing flow operations. For instance, factories utilizing AI are reported to increase their production efficiency by as much as 30%. With the continuous evolution of smart manufacturing practices, organizations that embrace these changes can expect significant reductions in operational costs while navigating the challenges posed by a resilient supply chain. By prioritizing flow efficiency in their systems, industries can strategically position themselves for sustained growth and competitiveness.

| Valve Type | Flow Efficiency (%) | Operational Cost Savings (%) | Maintenance Frequency (times/year) | Suitable Applications |

|---|---|---|---|---|

| Traditional Butterfly Valve | 60 | 10 | 4 | Water Treatment, HVAC |

| Electric Actuated Butterfly Valve | 70 | 15 | 3 | Chemical Processing, Food Industry |

| Segmented Ball Valve | 75 | 20 | 2 | Oil & Gas, Power Generation |

| V-Port Control Valve | 80 | 25 | 1 | Process Control, Water Supply |

| Pinch Valve | 85 | 30 | 2 | Slurry Transport, Mining |

The durability and maintenance of industrial valves play a pivotal role in optimizing operational efficiency. Recent studies indicate that traditional wafer butterfly valves often suffer from wear over time due to continuous exposure to harsh chemicals and fluctuating temperatures. According to a report by the Valve Manufacturers Association, nearly 30% of maintenance costs in industrial settings arise from valve-related issues. This highlights the urgent need for alternative solutions that boast enhanced longevity and reduced upkeep.

Innovative valve designs, such as pneumatic control valves and double offset butterfly valves, are emerging as reliable alternatives. For instance, research shows that double offset butterfly valves can offer a lifespan extending beyond 10 years, significantly reducing the frequency of replacements and maintenance interventions. Furthermore, materials like high-performance polymers and stainless steel are increasingly being incorporated into valve manufacturing, allowing for improved resistance against corrosion and thermal degradation. With data suggesting that a 20% reduction in downtime can be achieved by switching to these advanced options, industries are compelled to reassess their valve choices for better long-term reliability.

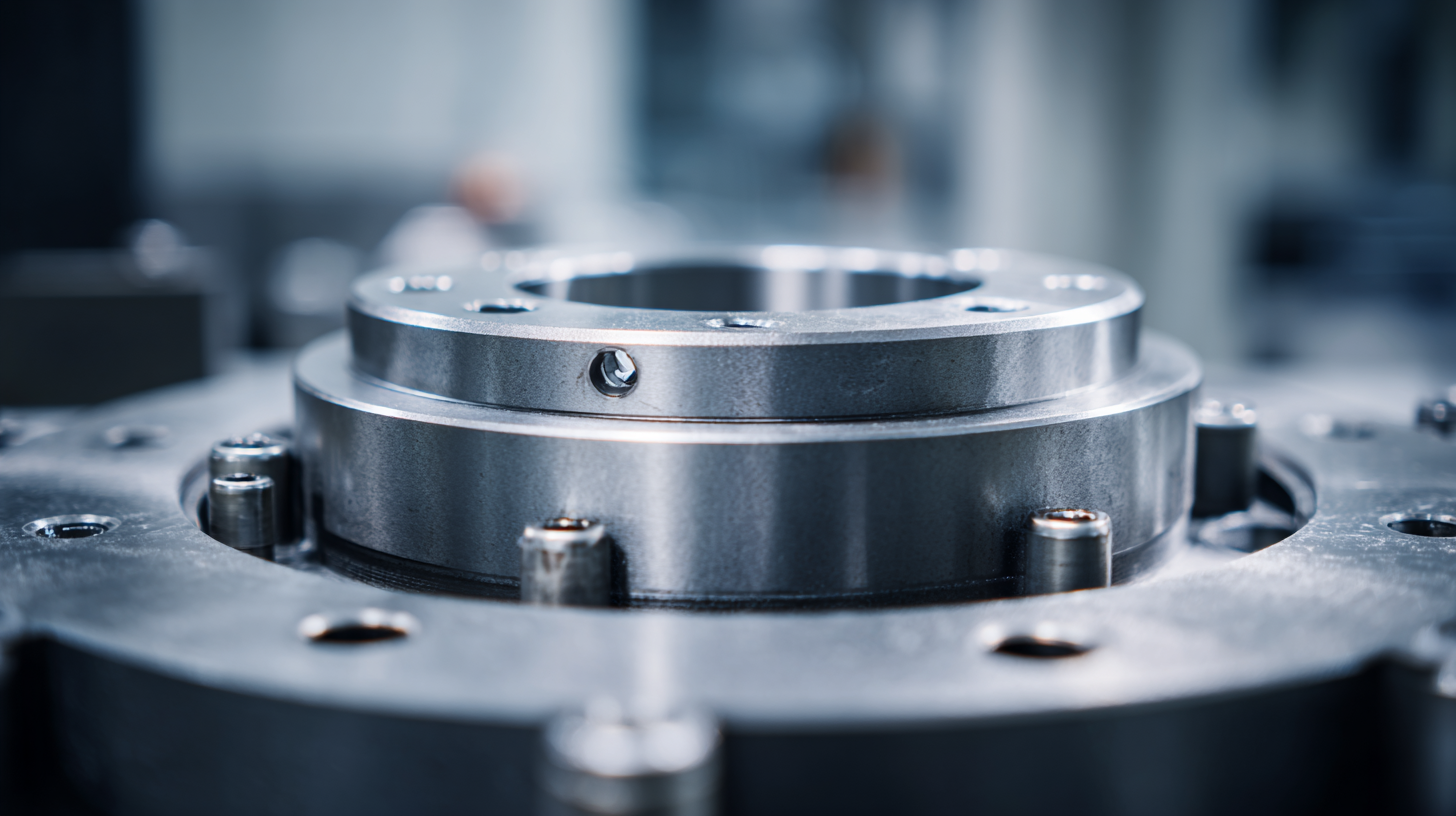

The evolution of valve manufacturing is significantly marked by the exploration of emerging materials that promise to enhance efficiency in industrial applications. Traditional wafer butterf ly valves, although widely used, often face limitations in performance due to material constraints. Therefore, manufacturers are increasingly turning to composites, thermoplastics, and advanced alloys that offer better resistance to corrosion, temperature extremes, and mechanical wear. These materials not only prolong the lifespan of the valves but also reduce maintenance costs, making them more appealing in sectors that require high reliability.

In addition to selecting innovative materials, advances in manufacturing techniques, such as 3D printing and precision machining, play a crucial role in the creation of next-generation valves. These technologies allow for custom designs that optimize flow characteristics and minimize pressure drops, enhancing overall system efficiency. Moreover, the integration of smart technologies enables real-time monitoring and predictive maintenance, further pushing the boundaries of what modern valves can achieve. The combination of these emerging materials and advanced manufacturing processes is poised to revolutionize the way industrial applications approach valve performance and efficiency.

In the modern industrial landscape, the quest for enhanced efficiency has driven companies to explore alternatives to traditional wafer butterfly valves. Recent case studies highlight the successful implementation of non-wafer valve technologies, demonstrating their effectiveness in optimizing performance across various sectors, including pumps and compressors. According to a report by the China Machinery Industry Federation, these alternative valves have shown a potential reduction in energy consumption by up to 15%, contributing significantly to operational efficiency.

A notable example from the Jiangsu-Zhejiang-Shanghai region involves a prominent enterprise that adopted a smart manufacturing approach, integrating advanced valve solutions into their production lines. Through this digital transformation, the company improved their response time and adjusted operational parameters in real-time, resulting in a 20% increase in throughput. The implementation of a "valve brain" system, designed for the pump and valve industry, exemplifies how small to medium-sized enterprises can leverage industrial internet innovations to optimize processes and foster competitive advantage.

These case studies underscore the critical role of non-wafer valves in modern manufacturing. As industries pivot towards smart solutions, the integration of advanced valve technologies not only aligns with efficiency goals but also positions companies to meet the demands of a rapidly evolving market.